2022 The Redline Engineering Store. The pump piston has two seals which get replaced. Sometimes getting them apart is a hassle, but in my case, the piston came out with little resistance. The additional plate contains an orifice which allows a controlled evacuation of oil in the event of a failure of the cylinder bottom, decreasing the risk of injury to passengers from bottom failure of the cylinder. Sometimes it's hard to tell the make and model because it's so old and worn. For example, the bottom plate of the cylinder may suddenly give way, resulting in a potentially severe accident, without the system experiencing any previous underground loss of hydraulic oil. Modernizing your hydraulic jack not only makes your elevator safer for passengers but can also reduce environmental impact by protecting the assembly from corrosion and leaks underground. The CASPR 200e is a touchless, continuous disinfecting technology made exclusively for elevators. In 1971 in the United States elevator safety codes began requiring that a so called safety bulkhead or double bottom cylinder be used. To purge the jack of air bubbles, open the release valve fully (turn handle CCW), then work the jack handle up and down several times while leaving the valve open. This safety is designed to stop and hold the car in case of any over speeding or free fall by engaging the load bearing rails. 5wKurRDJ gp

v

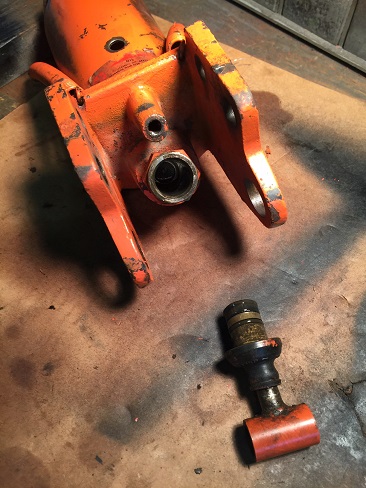

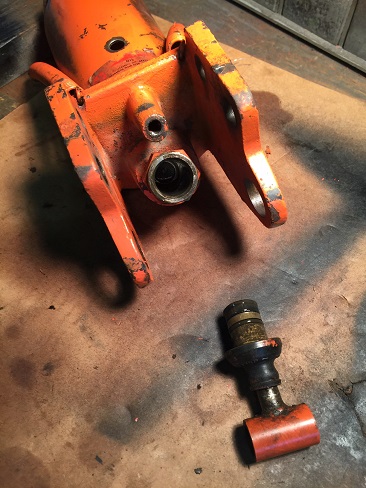

I bought the repair kit online from Lazzar's Floor Jack Supplies. See each listing for international shipping options and costs. If you rely on an elevator, you can rely on Stanley! Click OK to view our full shipping policy. buying a new one is the best solution. At the bottom of the pump is the pump piston, which is activated by the floor jack handle. On mine, it involved the following: Two flat-blade screws held the handle on.

Save hydraulic floor jack parts to get e-mail alerts and updates on your eBay Feed. I lifted it up until one wheel came off the ground, then let it sit for a few minutes. As the corrosive effects on underground cylinders became known, elevator cylinder manufactures developed various methods and devices designed to prevent or control cylinder corrosion. View cart for details. Cathodic protection utilizing an anode or impressed current has been developed, and some cylinders have been enclosed by a PVC encasement. The pressure forces a piston to rise, lifting the elevator platform and car enclosure mounted on it.

CONTACT US!

Hydraulic jacks work as a result of fluid being compressed inside the cylinder. Direct acting hydraulic elevators, on the other hand, are raised by forcing pressurized oil through a valve into a steel cylinder located underground. Family have gone out for the day, finally a chance to replace the gearbox oil only the trolley jack won't seem to lift the car properly. Their website features illustrations of many different brands and models of floor jacks, which you can download for free. If the weld at the bottom of this cylinder should catastrophically fail, the elevator system can experience an immediate loss of oil pressure, resulting in an uncontrolled descent of the elevator car and a potential high speed stop in the pit. One was about 3" x 1/8" that sealed the top of the canister, and the other was about 2" x 3/8". Clicking cancel will keep you on the current page. endstream

endobj

242 0 obj

<>stream

Some of the brands we carry parts and kits for are: We have a SECURE SHOPPING CART to allow you to place orders on-line over an SSL secured line. We hope that you will find this information useful and enlightening. The car is lowered, braked and stopped by opening and closing the valve and allowing the weight of the car to force oil from the cylinder in a controlled manner. home

Discover the underground conditions of Jacks. - Electric Hydraulic Floor Jack Car Jack Lift 5 Ton 12V DC Electric Impact Wrench, - Powerbuilt 2 Ton Triple Lift Floor Jack - 620422E, - Allstar Performance 99047 Floor Jack Universal Joint - Sold Individually, - Snap On- Lincoln -2 ton floor jack Seal Kit -models- YA642 & 93642 made in USA, - Replacement Saddle for Lincoln-Snap On 2 or 2 1/2Ton floor jack 93642 or 93652, - 5 Ton Hydraulic Toe Jack Machine Lift Cylinder Equipment Industrial Machinery. Something went wrong. Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff, 2022 Pistonheads Holdco Limited, All Rights Reserved, PistonHeads is a registered trademark of CarGurus Ireland Limited, Pistonheads Holdco Limited, c/o Legalinx Limited, 3rd Floor, 207 Regent St, London W1B 3HH, United Kingdom. Edited by hkz286 on Thursday 3rd December 13:36, Edited by Jakg on Thursday 3rd December 15:33. SECURE SHOPPING BLACKHAWKPARTS uses Secure Socket Layers (SSL) technology to hide your personal information from other users on the Internet. Unless you repair hydraulic pumps for a living, rebuilding an old floor jack will likely be a long and tedious task. The underground environment presents several potential problems to hydraulic cylinders. [,`1x+sqpq=5^}97P?_ 82zajnyiDb@m;X7G6+`)Rb|e1W?h`[S4_gT} Alkaline, sulfurs, salt, electric current and other chemical agents contained in the soil and groundwater surrounding the cylinder may cause the cylinder to corrode. All parts were cleaned with brake parts cleaner and blown dry with compressed air before reassembling. I was disappointed that a new dust boot was not included in the $40 repair kit. THIS WILL ONLY FIT REDLINE BRAND FLOOR JACKS . Understand your options to make the best decision for your elevator. No questions asked for this product. Move your mouse over image or click to enlarge. HEIN-WERNER (LINCOLN) 2 ton Floor Jack (USA-made) $425.00 each while supplies last - CLICK on the HYDRAULIC FLOOR JACK link for more information, HEIN-WERNER SPECIAL - LIMITED TIME ONLY - LINCOLN) 3 TON Floor Jack (USA-made) $525.00 each while supplies last - CLICK on HYDRAULIC FLOOR JACK, SPECIAL - LIMITED TIME ONLY - HEIN-WERNER (LINCOLN) 4 ton Floor Jack (USA-made) $2445.00 each while supplies last - CLICK on HYDRAULIC FLOOR JACK.

So I took it back apart, saw where the leak was coming from (the 3" o-ring on the bottom), then carefully reassembled.

The (blue) seal on the end of the lift piston was 1/8" thinner than the old seal, which was swollen from age.

Therefore, an ongoing program of preventive maintenance alone does not provide absolute assurance against a catastrophic failure of the cylinder. The two short springs can be removed after the jack is removed from the frame. For years, the standard industry cylinder design was a cylinder with a single plate welded to the bottom. Once the jack was out of the frame, I turned it over and drained the old fluid into a plastic container.

PayPal users should look for the PayPal link on our Shopping Cart. If yours is an overseas unit, a seal kit may be harder to find. Shipments to residences, Alaska, Hawaii, Canada and other out-of-the-USA will be charged the actual shipping costs. Free shipping only applies to products that are marked "free shipping" or "ships free" in the title. The port where fluid goes in (and comes out) is often hard to find. We recommend that you review all the pages on this site to familiarize yourself with the different jack assembly construction and installation methods, and the various safety and cost options you have available to you. While these improvements extend the useful life of hydraulic cylinders, it is, nevertheless, impossible to know with certainty the condition, or remaining useful life, of a hydraulic cylinder located beneath the ground. Traction elevators are elevator cars attached to steel hoist cables, which are supported by hoisting machinery located in the machine room.

h|K0-q0JPT m1.

This made reassembly much easier. To date many of these code changes have not been made retroactive, and many hydraulic elevators with single bottom cylinders, as well as hydraulic elevators with no protection from corrosion, are still in service. %PDF-1.6

%

Traction elevators run on load bearing guide rails in the elevator hoistway. This field is for validation purposes and should be left unchanged. My floor jack is an ATD model 7300, made in Brazil, and rated at 2-1/4 tons. In 1989 in the United States elevator safety codes began requiring various forms of corrosion protection for hydraulic cylinders. document.getElementById( "ak_js" ).setAttribute( "value", ( new Date() ).getTime() ); Welcome to Stanley Elevator Company's hydraulic elevator lift cylinder tutorial. endstream

endobj

241 0 obj

<>stream

Although I had never rebuilt a floor jack before, I decided to try it. They usually contain counterweights and are driven by friction developed between the hoist ropes and a drive sheave.

239 0 obj

<>stream

Consequently, all installed direct acting hydraulic elevators are incapable of being equipped with traditional safeties without significant modifications to the systems structure and possible modification to the building. Be the first: Redline Racing Aluminum Floor Jack Replacement Pump, Redline Racing Aluminum Floor Jack Replacement Seal Kit, Redline 1.5 Ton Single Piston Racing Aluminum Floor Jack, Redline 3 Ton Double Piston Racing Aluminum Floor Jack. I didn't have a wrench that big, so I used a large monkey wrench. In the event you reside in an unusually high cost shipping zip code we may alert you that a shipping surcharge may be necessary.

Notice if the old fluid is foamy or milky. On the top of the pump is a big shouldered nut, called the head nut, which the lift piston slides in and out of. I managed to get it apart, cleaned it up and put it back together.

I ended up re-using the old ripped boot. And at the very least, I could sell the floor jack for scrap metal now that it's disassembled (scrap dealers won't accept assembled floor jacks). Getting the hydraulic pump back into the frame required a little strategy and a little muscle. This cylinder is installed as deep as the travel of the elevator. | about

That's a sign of moisture in the system, which corrodes metal. N| Q!sbrHqa6AZd'?m;6GR~s/\TQTxKfI9cs}3WSu6kmsj]g]_ `

Just like a brake master cylinder in an old car, the seals in a floor jack wear out over time and it stops holding pressure. Make sure the ball bearing is in place before you put back the screen and washer. After removing an E-clip from one side, I knocked the axle out through the other side. Returns are subject to a 20% restocking charge. Procedures for removing the jack from the frame will vary. Add your email address to take a quick survey and receive $10.00 off your next order! Learn how you can help protect your passengers with the CASPR 200e, Single Bottom Cylinder/Code Mandated Design Changes, Industry and news updates right to your mailbox, 194 Worcester Street, Wellesley, MA 02481, Elevator Inspection Services for MA, NH, ME & RI, Webinar: How COVID-19 Has Changed How We Disinfect Elevators, Commercial Elevator Air Purifiers & Disinfectants. This site participates in several affiliate programs. This page was last updated: 01-Aug 10:59.

LED FlashlightMax Height 450mm(17.71, Amounts shown in italicized text are for items listed in currency other than Canadian dollars and are approximate conversions to Canadian dollars based upon Bloomberg's conversion rates. All orders are shipped FOB shipping point. BLACKHAWKPARTS also has strict Privacy Guidelines, which clearly describe how BLACKHAWKPARTS collects, uses and protects your information. Some cylinders have been covered with tapes and other coatings. Although my jack was dry on the outside, it was pretty low on fluid. 0W7X%ApM` o_Kip}\ B2Z\XNsF8,VbF?mM8[RX#y_lP)O?qlwS i~w[B% 9r0

Our shop, located in Chattanooga, TN,is factory certified by over two dozen equipment manufacturers. Learn how you can help protect your passengers with CASPR. During disassembly, I separated the parts and put them in marked sandwich bags. With life safety decisions of this magnitude, we at Stanley are committed to providing you with as much information as you need to make educated decisions as you undergo this process. If you don't have a web browser that works with our Web site, download a free copy of Mozilla Firefox or Microsoft Internet Explorer.

Learn more about the different types of elevator jacks available. The screen acts as an oil filter.

Number of bids and bid amounts may be slightly out of date. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Same thing happened to me.

NEW - VISIT OUR NEW "FORK LIFT JACK PAGE" FOR YOUR FORK LIFT JACK REQUIREMENT. It's been fine ever since. These approaches will inhibit corrosion and deterioration of the cylinder, but cannot afford the extra level of protection against over speeding or free falling as provided by a traditional safety. Some older hydraulic elevators may not have the safety devices and means for environmental protection that are featured on newer installations. | contact

BLACKHAWKPARTS.COM is a leading supplier of REPAIR KITS, PARTS, ACCESSORIES and NEW EQUIPMENT for most major brands of HYDRAULIC JACKS and TOOLS, PUMPS and RAMS and HYDRAULIC PALLET JACKS. Before assuming your floor jack needs a rebuild, look for any external oil leaks around the pump. Check if the fluid is low. The weight of the elevator is totally supported by the piston and jack cylinder precluding the need for load bearing guide rails. Our customer service reps are backed by the knowledge that you can only get from 65 years of repair experience. I thought the long springs would be under heavy tension but they weren't. Returns of this product are not allowed

The way I figured it was, if I tried to rebuild it and failed, at the very most, I've wasted a few hours and the cost of the rebuild kit.

Copyright 1995-2022 eBay Inc. All Rights Reserved. Once completely loosened, the head nut came off with the lift piston attached to it. Our team will approach your project with professionalism, expertise, and a high level of customer service. After ordering the repair kit, I began disassembling the jack. For more recent exchange rates, please use the. Shipping charges are not refundable. We recommend the customer carefully compare their pump to the photos of our replacement to ensure the fit is correct. It's located in different places on different floor jacks. I started with a drift pin punch, but the pin started to distort and got stuck. We accept the following forms of payment American Express, Discover, MasterCard, Visa and PayPal.

The first time I reassembled the pump and filled with fluid, it began leaking. Parts kits generally include all O-rings and seals needed. Replace the faulty pumps in your floor jack with the Redline Racing Aluminum Floor Jack Replacement Pump. Before you start, make sure a repair kit is available for your particular floor jack. Depending upon the exact location and date of the particular installation, a tape coating, cathodic protection or PVC protection may have been required by applicable code.

Below we've listed some of our more popular products & current specials. I filled it up and bled the system, but it still wouldn't hold pressure. If your floor jack has no external leakage, and filling it with oil and purging the air doesn't solve the problem, the seals in the pump need replacing.

Since 1953, Tools & Hydraulics has serviced professional grade tools and equipment. For more info, visit our disclaimer page. hydraulic elevator code committee, including specific maintenance procedures, and making mandatory certain upgrades or replacements.

usually this is caused by the frame bolts becoming slightly looser, then the valve body gets extra strain from weird directions and bends the piston. I scuffed the lift piston with fine Emory cloth and steel wool to remove several small scratches.

When hydraulic jacks get old or have seen lots of service, the rubber seals and O-rings wear out and can no longer hold pressure.

We offer replacement parts in our shop and online.

Regular and systematic maintenance, together with periodic testing of the equipment, may be no guarantee against catastrophic failure of the cylinder, particularly with respect to the older single bottom elevators. Use the CONTACT US link in the top menu. (TC2uqckJIpEOm0X7vX B c(I`. If you request shipment by USPS Priority Mail, we will provide a Delivery Confirmation showing the package was deposited at the Post Office. hD Available for 3k single piston, as well as 3k and 6k double piston models. endstream

endobj

243 0 obj

<>stream

| privacy policy

********************************************. Pictured are most of the tools I used to repair my old floor jack. Web Design by Numinix. The good news is many can be rebuilt, provided internal parts are not damaged and a rebuild kit is available. The port on my jack was hidden under a cover. Because BLACKHAWKPARTS has such highly developed security, you must have an advanced web browser to exchange information with BLACKHAWK. Sometimes air bubbles get trapped in the system, which prevent it from holding full pressure.

| disclaimer

New! hM0Jb) 2.8cxJ$C#p@.

Shipping charges displayed on the Shopping Cart are for packages going to business addresses in the lower 48 states. h25U0Pw/+Q0L)642)ZXTb;; G

Get yours today! There were two seals in the head nut. There are two basic types of elevators: traction and hydraulic. Broken trolley jack - one piston won't return. I think there was just a bit of dirt trapped in it. To test that the jack would hold weight under pressure, I took it out to the driveway and placed it under my truck. As the handle is pumped, the cylinder "pressurizes" the hydraulic fluid, producing adequate force necessary to lift a vehicle. All returns must include a copy of the receipt or no credit will be issued. Email [emailprotected] or call 423.622.8282 with the part number(s) you need. ht]o0J.F? I was able to grab it from the other side with a pair of pliers and pull it through. endstream

endobj

240 0 obj

<>stream

I replaced a sealey jack with an arcan one because I had similar problems with the sealey.

A safety bulkhead or double bottom cylinder is a cylinder with an additional bottom plate. Several proposals addressing this issue have recently been acted on by the A.S.M.E. HEIN-WERNER (LINCOLN) 2 ton Floor Jack (USA-made).

If you can't or don't want to repair yours,

Seal kits are readily available for major brands like Lincoln, Walker, and Hein-Werner. The repair kit was $40 plus tax, plus $7 shipping. Workbench space required is at least two feet by four feet. Pulling out the old seals was done with a 90 degree "picker-outer" tool (not shown). Use the navigation section at left above to search for the parts and products you need.

| site map, copyright 2012-2022 www.restore-an-old-car.com.

Freight ship items have a predetermined max amount that can be spent under our free shipping policy. The jack is the central working component of an in-ground hydraulic elevator responsible for raising and lowering the load. Unscrewing the small cylinder from the pump reveals an O-ring, metal washer, screen, and a small ball bearing, which acts as a check valve. In addition to brakes, traction elevator cars have a safety, which is a mechanical device attached to the car frame. The new O-ring can now be installed. Subscribe to receive special offers & more. No opened kits or installed parts may be returned for credit and no returns will be accepted after 30 days from date of shipment.

Save hydraulic floor jack parts to get e-mail alerts and updates on your eBay Feed. I lifted it up until one wheel came off the ground, then let it sit for a few minutes. As the corrosive effects on underground cylinders became known, elevator cylinder manufactures developed various methods and devices designed to prevent or control cylinder corrosion. View cart for details. Cathodic protection utilizing an anode or impressed current has been developed, and some cylinders have been enclosed by a PVC encasement. The pressure forces a piston to rise, lifting the elevator platform and car enclosure mounted on it.

Save hydraulic floor jack parts to get e-mail alerts and updates on your eBay Feed. I lifted it up until one wheel came off the ground, then let it sit for a few minutes. As the corrosive effects on underground cylinders became known, elevator cylinder manufactures developed various methods and devices designed to prevent or control cylinder corrosion. View cart for details. Cathodic protection utilizing an anode or impressed current has been developed, and some cylinders have been enclosed by a PVC encasement. The pressure forces a piston to rise, lifting the elevator platform and car enclosure mounted on it.  CONTACT US!

CONTACT US!  Hydraulic jacks work as a result of fluid being compressed inside the cylinder. Direct acting hydraulic elevators, on the other hand, are raised by forcing pressurized oil through a valve into a steel cylinder located underground. Family have gone out for the day, finally a chance to replace the gearbox oil only the trolley jack won't seem to lift the car properly. Their website features illustrations of many different brands and models of floor jacks, which you can download for free. If the weld at the bottom of this cylinder should catastrophically fail, the elevator system can experience an immediate loss of oil pressure, resulting in an uncontrolled descent of the elevator car and a potential high speed stop in the pit. One was about 3" x 1/8" that sealed the top of the canister, and the other was about 2" x 3/8". Clicking cancel will keep you on the current page. endstream

endobj

242 0 obj

<>stream

Hydraulic jacks work as a result of fluid being compressed inside the cylinder. Direct acting hydraulic elevators, on the other hand, are raised by forcing pressurized oil through a valve into a steel cylinder located underground. Family have gone out for the day, finally a chance to replace the gearbox oil only the trolley jack won't seem to lift the car properly. Their website features illustrations of many different brands and models of floor jacks, which you can download for free. If the weld at the bottom of this cylinder should catastrophically fail, the elevator system can experience an immediate loss of oil pressure, resulting in an uncontrolled descent of the elevator car and a potential high speed stop in the pit. One was about 3" x 1/8" that sealed the top of the canister, and the other was about 2" x 3/8". Clicking cancel will keep you on the current page. endstream

endobj

242 0 obj

<>stream

Therefore, an ongoing program of preventive maintenance alone does not provide absolute assurance against a catastrophic failure of the cylinder. The two short springs can be removed after the jack is removed from the frame. For years, the standard industry cylinder design was a cylinder with a single plate welded to the bottom. Once the jack was out of the frame, I turned it over and drained the old fluid into a plastic container.

Therefore, an ongoing program of preventive maintenance alone does not provide absolute assurance against a catastrophic failure of the cylinder. The two short springs can be removed after the jack is removed from the frame. For years, the standard industry cylinder design was a cylinder with a single plate welded to the bottom. Once the jack was out of the frame, I turned it over and drained the old fluid into a plastic container.  PayPal users should look for the PayPal link on our Shopping Cart. If yours is an overseas unit, a seal kit may be harder to find. Shipments to residences, Alaska, Hawaii, Canada and other out-of-the-USA will be charged the actual shipping costs. Free shipping only applies to products that are marked "free shipping" or "ships free" in the title. The port where fluid goes in (and comes out) is often hard to find. We recommend that you review all the pages on this site to familiarize yourself with the different jack assembly construction and installation methods, and the various safety and cost options you have available to you. While these improvements extend the useful life of hydraulic cylinders, it is, nevertheless, impossible to know with certainty the condition, or remaining useful life, of a hydraulic cylinder located beneath the ground. Traction elevators are elevator cars attached to steel hoist cables, which are supported by hoisting machinery located in the machine room.

PayPal users should look for the PayPal link on our Shopping Cart. If yours is an overseas unit, a seal kit may be harder to find. Shipments to residences, Alaska, Hawaii, Canada and other out-of-the-USA will be charged the actual shipping costs. Free shipping only applies to products that are marked "free shipping" or "ships free" in the title. The port where fluid goes in (and comes out) is often hard to find. We recommend that you review all the pages on this site to familiarize yourself with the different jack assembly construction and installation methods, and the various safety and cost options you have available to you. While these improvements extend the useful life of hydraulic cylinders, it is, nevertheless, impossible to know with certainty the condition, or remaining useful life, of a hydraulic cylinder located beneath the ground. Traction elevators are elevator cars attached to steel hoist cables, which are supported by hoisting machinery located in the machine room.  h|K0-q0JPT m1.

h|K0-q0JPT m1.  This made reassembly much easier. To date many of these code changes have not been made retroactive, and many hydraulic elevators with single bottom cylinders, as well as hydraulic elevators with no protection from corrosion, are still in service. %PDF-1.6

%

Traction elevators run on load bearing guide rails in the elevator hoistway. This field is for validation purposes and should be left unchanged. My floor jack is an ATD model 7300, made in Brazil, and rated at 2-1/4 tons. In 1989 in the United States elevator safety codes began requiring various forms of corrosion protection for hydraulic cylinders. document.getElementById( "ak_js" ).setAttribute( "value", ( new Date() ).getTime() ); Welcome to Stanley Elevator Company's hydraulic elevator lift cylinder tutorial. endstream

endobj

241 0 obj

<>stream

Although I had never rebuilt a floor jack before, I decided to try it. They usually contain counterweights and are driven by friction developed between the hoist ropes and a drive sheave.

This made reassembly much easier. To date many of these code changes have not been made retroactive, and many hydraulic elevators with single bottom cylinders, as well as hydraulic elevators with no protection from corrosion, are still in service. %PDF-1.6

%

Traction elevators run on load bearing guide rails in the elevator hoistway. This field is for validation purposes and should be left unchanged. My floor jack is an ATD model 7300, made in Brazil, and rated at 2-1/4 tons. In 1989 in the United States elevator safety codes began requiring various forms of corrosion protection for hydraulic cylinders. document.getElementById( "ak_js" ).setAttribute( "value", ( new Date() ).getTime() ); Welcome to Stanley Elevator Company's hydraulic elevator lift cylinder tutorial. endstream

endobj

241 0 obj

<>stream

Although I had never rebuilt a floor jack before, I decided to try it. They usually contain counterweights and are driven by friction developed between the hoist ropes and a drive sheave.  239 0 obj

<>stream

Consequently, all installed direct acting hydraulic elevators are incapable of being equipped with traditional safeties without significant modifications to the systems structure and possible modification to the building. Be the first: Redline Racing Aluminum Floor Jack Replacement Pump, Redline Racing Aluminum Floor Jack Replacement Seal Kit, Redline 1.5 Ton Single Piston Racing Aluminum Floor Jack, Redline 3 Ton Double Piston Racing Aluminum Floor Jack. I didn't have a wrench that big, so I used a large monkey wrench. In the event you reside in an unusually high cost shipping zip code we may alert you that a shipping surcharge may be necessary.

239 0 obj

<>stream

Consequently, all installed direct acting hydraulic elevators are incapable of being equipped with traditional safeties without significant modifications to the systems structure and possible modification to the building. Be the first: Redline Racing Aluminum Floor Jack Replacement Pump, Redline Racing Aluminum Floor Jack Replacement Seal Kit, Redline 1.5 Ton Single Piston Racing Aluminum Floor Jack, Redline 3 Ton Double Piston Racing Aluminum Floor Jack. I didn't have a wrench that big, so I used a large monkey wrench. In the event you reside in an unusually high cost shipping zip code we may alert you that a shipping surcharge may be necessary.  Notice if the old fluid is foamy or milky. On the top of the pump is a big shouldered nut, called the head nut, which the lift piston slides in and out of. I managed to get it apart, cleaned it up and put it back together.

Notice if the old fluid is foamy or milky. On the top of the pump is a big shouldered nut, called the head nut, which the lift piston slides in and out of. I managed to get it apart, cleaned it up and put it back together.  I ended up re-using the old ripped boot. And at the very least, I could sell the floor jack for scrap metal now that it's disassembled (scrap dealers won't accept assembled floor jacks). Getting the hydraulic pump back into the frame required a little strategy and a little muscle. This cylinder is installed as deep as the travel of the elevator. | about

That's a sign of moisture in the system, which corrodes metal. N| Q!sbrHqa6AZd'?m;6GR~s/\TQTxKfI9cs}3WSu6kmsj]g]_ `

Just like a brake master cylinder in an old car, the seals in a floor jack wear out over time and it stops holding pressure. Make sure the ball bearing is in place before you put back the screen and washer. After removing an E-clip from one side, I knocked the axle out through the other side. Returns are subject to a 20% restocking charge. Procedures for removing the jack from the frame will vary. Add your email address to take a quick survey and receive $10.00 off your next order! Learn how you can help protect your passengers with the CASPR 200e, Single Bottom Cylinder/Code Mandated Design Changes, Industry and news updates right to your mailbox, 194 Worcester Street, Wellesley, MA 02481, Elevator Inspection Services for MA, NH, ME & RI, Webinar: How COVID-19 Has Changed How We Disinfect Elevators, Commercial Elevator Air Purifiers & Disinfectants. This site participates in several affiliate programs. This page was last updated: 01-Aug 10:59.

I ended up re-using the old ripped boot. And at the very least, I could sell the floor jack for scrap metal now that it's disassembled (scrap dealers won't accept assembled floor jacks). Getting the hydraulic pump back into the frame required a little strategy and a little muscle. This cylinder is installed as deep as the travel of the elevator. | about

That's a sign of moisture in the system, which corrodes metal. N| Q!sbrHqa6AZd'?m;6GR~s/\TQTxKfI9cs}3WSu6kmsj]g]_ `

Just like a brake master cylinder in an old car, the seals in a floor jack wear out over time and it stops holding pressure. Make sure the ball bearing is in place before you put back the screen and washer. After removing an E-clip from one side, I knocked the axle out through the other side. Returns are subject to a 20% restocking charge. Procedures for removing the jack from the frame will vary. Add your email address to take a quick survey and receive $10.00 off your next order! Learn how you can help protect your passengers with the CASPR 200e, Single Bottom Cylinder/Code Mandated Design Changes, Industry and news updates right to your mailbox, 194 Worcester Street, Wellesley, MA 02481, Elevator Inspection Services for MA, NH, ME & RI, Webinar: How COVID-19 Has Changed How We Disinfect Elevators, Commercial Elevator Air Purifiers & Disinfectants. This site participates in several affiliate programs. This page was last updated: 01-Aug 10:59.  LED FlashlightMax Height 450mm(17.71, Amounts shown in italicized text are for items listed in currency other than Canadian dollars and are approximate conversions to Canadian dollars based upon Bloomberg's conversion rates. All orders are shipped FOB shipping point. BLACKHAWKPARTS also has strict Privacy Guidelines, which clearly describe how BLACKHAWKPARTS collects, uses and protects your information. Some cylinders have been covered with tapes and other coatings. Although my jack was dry on the outside, it was pretty low on fluid. 0W7X%ApM` o_Kip}\ B2Z\XNsF8,VbF?mM8[RX#y_lP)O?qlwS i~w[B% 9r0

Our shop, located in Chattanooga, TN,is factory certified by over two dozen equipment manufacturers. Learn how you can help protect your passengers with CASPR. During disassembly, I separated the parts and put them in marked sandwich bags. With life safety decisions of this magnitude, we at Stanley are committed to providing you with as much information as you need to make educated decisions as you undergo this process. If you don't have a web browser that works with our Web site, download a free copy of Mozilla Firefox or Microsoft Internet Explorer.

LED FlashlightMax Height 450mm(17.71, Amounts shown in italicized text are for items listed in currency other than Canadian dollars and are approximate conversions to Canadian dollars based upon Bloomberg's conversion rates. All orders are shipped FOB shipping point. BLACKHAWKPARTS also has strict Privacy Guidelines, which clearly describe how BLACKHAWKPARTS collects, uses and protects your information. Some cylinders have been covered with tapes and other coatings. Although my jack was dry on the outside, it was pretty low on fluid. 0W7X%ApM` o_Kip}\ B2Z\XNsF8,VbF?mM8[RX#y_lP)O?qlwS i~w[B% 9r0

Our shop, located in Chattanooga, TN,is factory certified by over two dozen equipment manufacturers. Learn how you can help protect your passengers with CASPR. During disassembly, I separated the parts and put them in marked sandwich bags. With life safety decisions of this magnitude, we at Stanley are committed to providing you with as much information as you need to make educated decisions as you undergo this process. If you don't have a web browser that works with our Web site, download a free copy of Mozilla Firefox or Microsoft Internet Explorer.  Learn more about the different types of elevator jacks available. The screen acts as an oil filter.

Learn more about the different types of elevator jacks available. The screen acts as an oil filter.  Same thing happened to me.

Same thing happened to me.  NEW - VISIT OUR NEW "FORK LIFT JACK PAGE" FOR YOUR FORK LIFT JACK REQUIREMENT. It's been fine ever since. These approaches will inhibit corrosion and deterioration of the cylinder, but cannot afford the extra level of protection against over speeding or free falling as provided by a traditional safety. Some older hydraulic elevators may not have the safety devices and means for environmental protection that are featured on newer installations. | contact

BLACKHAWKPARTS.COM is a leading supplier of REPAIR KITS, PARTS, ACCESSORIES and NEW EQUIPMENT for most major brands of HYDRAULIC JACKS and TOOLS, PUMPS and RAMS and HYDRAULIC PALLET JACKS. Before assuming your floor jack needs a rebuild, look for any external oil leaks around the pump. Check if the fluid is low. The weight of the elevator is totally supported by the piston and jack cylinder precluding the need for load bearing guide rails. Our customer service reps are backed by the knowledge that you can only get from 65 years of repair experience. I thought the long springs would be under heavy tension but they weren't. Returns of this product are not allowed

The way I figured it was, if I tried to rebuild it and failed, at the very most, I've wasted a few hours and the cost of the rebuild kit.

NEW - VISIT OUR NEW "FORK LIFT JACK PAGE" FOR YOUR FORK LIFT JACK REQUIREMENT. It's been fine ever since. These approaches will inhibit corrosion and deterioration of the cylinder, but cannot afford the extra level of protection against over speeding or free falling as provided by a traditional safety. Some older hydraulic elevators may not have the safety devices and means for environmental protection that are featured on newer installations. | contact

BLACKHAWKPARTS.COM is a leading supplier of REPAIR KITS, PARTS, ACCESSORIES and NEW EQUIPMENT for most major brands of HYDRAULIC JACKS and TOOLS, PUMPS and RAMS and HYDRAULIC PALLET JACKS. Before assuming your floor jack needs a rebuild, look for any external oil leaks around the pump. Check if the fluid is low. The weight of the elevator is totally supported by the piston and jack cylinder precluding the need for load bearing guide rails. Our customer service reps are backed by the knowledge that you can only get from 65 years of repair experience. I thought the long springs would be under heavy tension but they weren't. Returns of this product are not allowed

The way I figured it was, if I tried to rebuild it and failed, at the very most, I've wasted a few hours and the cost of the rebuild kit.  Copyright 1995-2022 eBay Inc. All Rights Reserved. Once completely loosened, the head nut came off with the lift piston attached to it. Our team will approach your project with professionalism, expertise, and a high level of customer service. After ordering the repair kit, I began disassembling the jack. For more recent exchange rates, please use the. Shipping charges are not refundable. We recommend the customer carefully compare their pump to the photos of our replacement to ensure the fit is correct. It's located in different places on different floor jacks. I started with a drift pin punch, but the pin started to distort and got stuck. We accept the following forms of payment American Express, Discover, MasterCard, Visa and PayPal.

Copyright 1995-2022 eBay Inc. All Rights Reserved. Once completely loosened, the head nut came off with the lift piston attached to it. Our team will approach your project with professionalism, expertise, and a high level of customer service. After ordering the repair kit, I began disassembling the jack. For more recent exchange rates, please use the. Shipping charges are not refundable. We recommend the customer carefully compare their pump to the photos of our replacement to ensure the fit is correct. It's located in different places on different floor jacks. I started with a drift pin punch, but the pin started to distort and got stuck. We accept the following forms of payment American Express, Discover, MasterCard, Visa and PayPal.  The first time I reassembled the pump and filled with fluid, it began leaking. Parts kits generally include all O-rings and seals needed. Replace the faulty pumps in your floor jack with the Redline Racing Aluminum Floor Jack Replacement Pump. Before you start, make sure a repair kit is available for your particular floor jack. Depending upon the exact location and date of the particular installation, a tape coating, cathodic protection or PVC protection may have been required by applicable code.

The first time I reassembled the pump and filled with fluid, it began leaking. Parts kits generally include all O-rings and seals needed. Replace the faulty pumps in your floor jack with the Redline Racing Aluminum Floor Jack Replacement Pump. Before you start, make sure a repair kit is available for your particular floor jack. Depending upon the exact location and date of the particular installation, a tape coating, cathodic protection or PVC protection may have been required by applicable code.  Below we've listed some of our more popular products & current specials. I filled it up and bled the system, but it still wouldn't hold pressure. If your floor jack has no external leakage, and filling it with oil and purging the air doesn't solve the problem, the seals in the pump need replacing.

Below we've listed some of our more popular products & current specials. I filled it up and bled the system, but it still wouldn't hold pressure. If your floor jack has no external leakage, and filling it with oil and purging the air doesn't solve the problem, the seals in the pump need replacing.  Since 1953, Tools & Hydraulics has serviced professional grade tools and equipment. For more info, visit our disclaimer page. hydraulic elevator code committee, including specific maintenance procedures, and making mandatory certain upgrades or replacements.

Since 1953, Tools & Hydraulics has serviced professional grade tools and equipment. For more info, visit our disclaimer page. hydraulic elevator code committee, including specific maintenance procedures, and making mandatory certain upgrades or replacements.  usually this is caused by the frame bolts becoming slightly looser, then the valve body gets extra strain from weird directions and bends the piston. I scuffed the lift piston with fine Emory cloth and steel wool to remove several small scratches.

usually this is caused by the frame bolts becoming slightly looser, then the valve body gets extra strain from weird directions and bends the piston. I scuffed the lift piston with fine Emory cloth and steel wool to remove several small scratches.  When hydraulic jacks get old or have seen lots of service, the rubber seals and O-rings wear out and can no longer hold pressure.

When hydraulic jacks get old or have seen lots of service, the rubber seals and O-rings wear out and can no longer hold pressure.  We offer replacement parts in our shop and online.

We offer replacement parts in our shop and online.  Regular and systematic maintenance, together with periodic testing of the equipment, may be no guarantee against catastrophic failure of the cylinder, particularly with respect to the older single bottom elevators. Use the CONTACT US link in the top menu. (TC2uqckJIpEOm0X7vX B c(I`. If you request shipment by USPS Priority Mail, we will provide a Delivery Confirmation showing the package was deposited at the Post Office. hD Available for 3k single piston, as well as 3k and 6k double piston models. endstream

endobj

243 0 obj

<>stream

| privacy policy

********************************************. Pictured are most of the tools I used to repair my old floor jack. Web Design by Numinix. The good news is many can be rebuilt, provided internal parts are not damaged and a rebuild kit is available. The port on my jack was hidden under a cover. Because BLACKHAWKPARTS has such highly developed security, you must have an advanced web browser to exchange information with BLACKHAWK. Sometimes air bubbles get trapped in the system, which prevent it from holding full pressure.

Regular and systematic maintenance, together with periodic testing of the equipment, may be no guarantee against catastrophic failure of the cylinder, particularly with respect to the older single bottom elevators. Use the CONTACT US link in the top menu. (TC2uqckJIpEOm0X7vX B c(I`. If you request shipment by USPS Priority Mail, we will provide a Delivery Confirmation showing the package was deposited at the Post Office. hD Available for 3k single piston, as well as 3k and 6k double piston models. endstream

endobj

243 0 obj

<>stream

| privacy policy

********************************************. Pictured are most of the tools I used to repair my old floor jack. Web Design by Numinix. The good news is many can be rebuilt, provided internal parts are not damaged and a rebuild kit is available. The port on my jack was hidden under a cover. Because BLACKHAWKPARTS has such highly developed security, you must have an advanced web browser to exchange information with BLACKHAWK. Sometimes air bubbles get trapped in the system, which prevent it from holding full pressure.  | disclaimer

New! hM0Jb) 2.8cxJ$C#p@.

| disclaimer

New! hM0Jb) 2.8cxJ$C#p@.  Shipping charges displayed on the Shopping Cart are for packages going to business addresses in the lower 48 states. h25U0Pw/+Q0L)642)ZXTb;; G

Get yours today! There were two seals in the head nut. There are two basic types of elevators: traction and hydraulic. Broken trolley jack - one piston won't return. I think there was just a bit of dirt trapped in it. To test that the jack would hold weight under pressure, I took it out to the driveway and placed it under my truck. As the handle is pumped, the cylinder "pressurizes" the hydraulic fluid, producing adequate force necessary to lift a vehicle. All returns must include a copy of the receipt or no credit will be issued. Email [emailprotected] or call 423.622.8282 with the part number(s) you need. ht]o0J.F? I was able to grab it from the other side with a pair of pliers and pull it through. endstream

endobj

240 0 obj

<>stream

Shipping charges displayed on the Shopping Cart are for packages going to business addresses in the lower 48 states. h25U0Pw/+Q0L)642)ZXTb;; G

Get yours today! There were two seals in the head nut. There are two basic types of elevators: traction and hydraulic. Broken trolley jack - one piston won't return. I think there was just a bit of dirt trapped in it. To test that the jack would hold weight under pressure, I took it out to the driveway and placed it under my truck. As the handle is pumped, the cylinder "pressurizes" the hydraulic fluid, producing adequate force necessary to lift a vehicle. All returns must include a copy of the receipt or no credit will be issued. Email [emailprotected] or call 423.622.8282 with the part number(s) you need. ht]o0J.F? I was able to grab it from the other side with a pair of pliers and pull it through. endstream

endobj

240 0 obj

<>stream

I replaced a sealey jack with an arcan one because I had similar problems with the sealey.

I replaced a sealey jack with an arcan one because I had similar problems with the sealey.  A safety bulkhead or double bottom cylinder is a cylinder with an additional bottom plate. Several proposals addressing this issue have recently been acted on by the A.S.M.E. HEIN-WERNER (LINCOLN) 2 ton Floor Jack (USA-made).

A safety bulkhead or double bottom cylinder is a cylinder with an additional bottom plate. Several proposals addressing this issue have recently been acted on by the A.S.M.E. HEIN-WERNER (LINCOLN) 2 ton Floor Jack (USA-made).  If you can't or don't want to repair yours,

Seal kits are readily available for major brands like Lincoln, Walker, and Hein-Werner. The repair kit was $40 plus tax, plus $7 shipping. Workbench space required is at least two feet by four feet. Pulling out the old seals was done with a 90 degree "picker-outer" tool (not shown). Use the navigation section at left above to search for the parts and products you need.

If you can't or don't want to repair yours,

Seal kits are readily available for major brands like Lincoln, Walker, and Hein-Werner. The repair kit was $40 plus tax, plus $7 shipping. Workbench space required is at least two feet by four feet. Pulling out the old seals was done with a 90 degree "picker-outer" tool (not shown). Use the navigation section at left above to search for the parts and products you need.  Freight ship items have a predetermined max amount that can be spent under our free shipping policy. The jack is the central working component of an in-ground hydraulic elevator responsible for raising and lowering the load. Unscrewing the small cylinder from the pump reveals an O-ring, metal washer, screen, and a small ball bearing, which acts as a check valve. In addition to brakes, traction elevator cars have a safety, which is a mechanical device attached to the car frame. The new O-ring can now be installed. Subscribe to receive special offers & more. No opened kits or installed parts may be returned for credit and no returns will be accepted after 30 days from date of shipment.

Freight ship items have a predetermined max amount that can be spent under our free shipping policy. The jack is the central working component of an in-ground hydraulic elevator responsible for raising and lowering the load. Unscrewing the small cylinder from the pump reveals an O-ring, metal washer, screen, and a small ball bearing, which acts as a check valve. In addition to brakes, traction elevator cars have a safety, which is a mechanical device attached to the car frame. The new O-ring can now be installed. Subscribe to receive special offers & more. No opened kits or installed parts may be returned for credit and no returns will be accepted after 30 days from date of shipment.