+ 2% =, 3

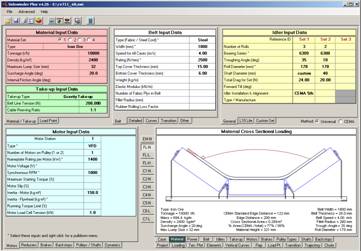

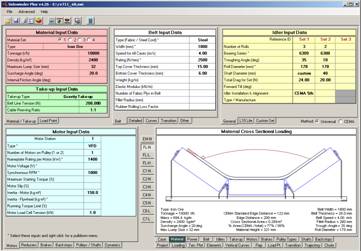

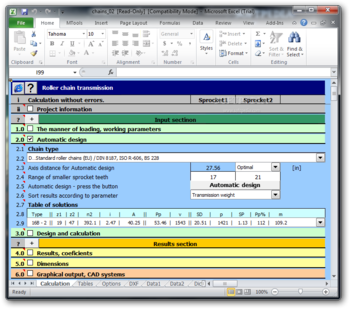

When the head and tail pulley are the same size:L=(D+d)/2 x 3.1416+2CWhen one pulley is larger than the other pulley:L=(D+d)/2 x 3.1416+2C+(D-d)2/4c, At one time when the load is known per square foot:P= G1 x C(in feet)x W (in feet)At one time when load is known by pounds per hour:P=G2/(S x 60) x C(in feet), Level Conveyors:HP=(F x S x (P+M))/33,000Inclined Conveyors:HP=((P x B)+(P+M)x F x S)/33,000, Pull needed to move belt and load horizontally:E= F x (P+M), Total tension to move belt and load horizontally:E2= E+E1, Additional tension required to prevent slippage on drive pulley:E1=Ex K, Determines the working strength of the belt to handle the job on per inch of width basis:T= E2/W. Copyright 2017 McGinty Conveyors Inc. All rights reserved. Divide this distance by carrier spacing to determine number of loaded carriers.

STEP #2: DETERMINE QUANTITY OF LOADED AND UNLOADED CARRIERS.

by the number of feet of chain. This calculation provides the linear distance traversed by a point on the conveyor belt in one minute.

Please help us to share our service with your friends. The required number of carriers is equal to the total conveyor length divided by the carrier spacing. When adverse environment conditions exist or the conveyor is abnormally long or complex and exceeds the chain pull capacity of one drive, a progressive chain pull computation is necessary where the friction losses are progressively calculated and accumulated through the path along the conveyor. Trigonometry can provide the sine of any angle, but the following angles of slope are most used.

resultant plus 2% for the 90 curve. to 3 = 53.1 ft. x .4575 lbs./ft. to 4 = 13.6 ft. x .4575 lbs./ft. Distance traveled, or displacement, per a change in time is the definition of velocity, or speed and direction. Distance traveled (displacement) per a change in time is the definition of velocity (speed and direction). In Figure #2, a conveyor is shown identical to Figure #1 except for the addition of an incline and decline. In Figure #1 a simple system about 115'-0" long is shown with four horizontal curves. + 6.97 lbs. To arrive at this figure, it is necessary to add the lift load and the friction factors, expressed as a small percentage of the live load, which act as resistance to the progress of the conveyor.

Count how many full rotations are made by the roller in one minute.

However, by knowing the value of the various factors, the total chain pull may be determined by the point to point accumulation method of calculation. The net vertical rise (in feet) will be considered the total lifting height of the conveyor. Jesse Randall studied mathematics and physics and works as an embedded electronics engineer, developing microcontroller firmware and digital interfaces.

There are few, if any, short cuts in the process of determining the chain pull on an endless chain conveyor.

+ 2% =, 2 + (6'-0 x 30 lbs./ft.) Online Store Terms and Warranty. @ 1.50% = 15 lbs. Measure the diameter of the rollers around which the conveyor belt is wrapped. 0 lbs.

Next, divide by 12 to arrive at 314 feet, then divide by 5,280, to convert to miles per hour, 12 inches = 1 foot and 5,280 feet = 1 mile. Pi is a dimensionless factor, meaning it does not matter whether inches, centimeters or any other units of measurement are used.

We also share information about your use of our site with our social media, advertising, and analytics partners who may combine it with other information that you've provided or that we have collected from your use of our services. =. 0 Multiply the diameter of the roller by pi, 3.14159. to 2 = 8.1 ft. x 4575 lbs./ft. A.

Measure the revolutions per minute of the rollers.

E. Total of A, B, C, D = total live load on the conveyor system. + 2% =, 5 Introduction of inclines and declines in a system further complicates chain pull calculation by adding to the forces. Chain Pull, SHORT CUT METHOD OF CHAIN PULL CALCULATION (Approximation Only). chain pull. + 3.13 lbs. + 3.13 lbs.

We are a non-profit group that run this service to share documents. The speed at which the conveyor belt moves depends on the size of the rollers and their revolutions per minute. To calculate this force, determine the difference in elevation of all the vertical curves traveling upward in the system. We use cookies to personalize content and analyze traffic. The following formula provides a result of .45 pounds per foot. For example, a roller with a diameter of 2 inches, has a circumference of 2 x 3.14159 or 6.28 inches. About Us | Products | Services | Resources | Contact Us | Site Map + 6.97 lbs. Whether you need help solving quadratic equations, inspiration for the upcoming science fair or the latest update on a major storm, Sciencing is here to help. When the loads are spaced under 2'-0" on centers, the formula of the total pounds per foot multiplied by the rise in feet can be used to determine the additional force in pounds for the inclined section. The lift load is the amount of force required to pull the live load upward along the vertical curves in the entire system. + 2% =, 4 to 1 = 11 ft. x .4575 lbs./ft. To keep our site running, we need your help to cover our server cost (about $500/m), a small donation will help us a lot. to 0 = 33.8 ft. x .4575 lbs./ft. =, 1 Get product updates and company news delivered directly to your inbox. B. per foot (including chain @ 2.5 lbs. chain pull.

per foot) x 100'-0" or 1000 lbs. Manufacturers and grocery stores typically use conveyors to move products along a specific path. Speak With A Sparks Representative For Help With Your Conveyor Belt Calculations. A. Many factors, which vary greatly from system to system, influence the end result. Next, divide by 12, then divide by 5,280, to convert to miles per hour (12 inches = 1 foot and 5,280 feet = 1 mile). Objects and materials placed on top of the conveyor belt will be moved from one edge to the other as the rollers spin. "WE SERVICE WHAT WE SELL" In systems having multiple rises and falls, this may be treated somewhat differently, depending on loading patterns. Please copy and paste this embed script to where you want to embed. Due to the elevations changes, the formula for finding the pounds per foot chain pull is arranged differently because it must be assumed that at some point the incline will be loaded and the decline empty. Product carrier weight, product weight, coefficient of friction, track curves, inclines, declines, temperature and lubrication are some of the principle items affecting chain pull.

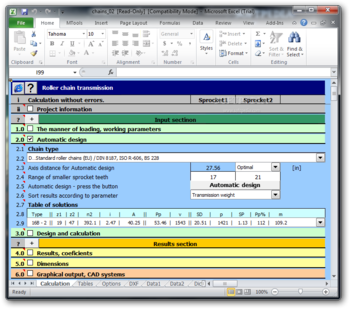

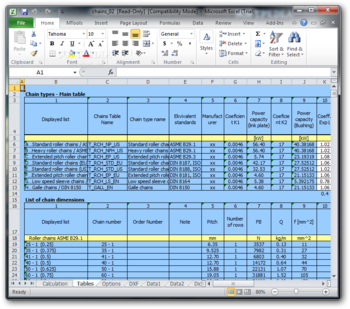

It will be seen that straight conveyor has a friction factor of 1.50%. Design Data - Step 4: Chain Pull Calculation. He has been writing on technology-related subjects since 2000. to 6 = 8.1 ft. x .4575 lbs./ft.

Multiply one more time by 60 to arrive at the total inches traveled per hour which equals 3,768. + 2% =, 1 2022 Leaf Group Ltd. / Leaf Group Media, All Rights Reserved. Friction resistance is found in the bearings of the chain wheels, curves, and the drive unit itself.

This can be seen in the chain pull calculation for the conveyor in Figure #2 from point #3 to #4. and the 2% friction for the 90 curve is added. Multiply weight of the chain (3.0 lbs.)

STEP #2: DETERMINE QUANTITY OF LOADED AND UNLOADED CARRIERS.

STEP #2: DETERMINE QUANTITY OF LOADED AND UNLOADED CARRIERS.

by the number of feet of chain. This calculation provides the linear distance traversed by a point on the conveyor belt in one minute.

by the number of feet of chain. This calculation provides the linear distance traversed by a point on the conveyor belt in one minute.  Please help us to share our service with your friends. The required number of carriers is equal to the total conveyor length divided by the carrier spacing. When adverse environment conditions exist or the conveyor is abnormally long or complex and exceeds the chain pull capacity of one drive, a progressive chain pull computation is necessary where the friction losses are progressively calculated and accumulated through the path along the conveyor. Trigonometry can provide the sine of any angle, but the following angles of slope are most used.

Please help us to share our service with your friends. The required number of carriers is equal to the total conveyor length divided by the carrier spacing. When adverse environment conditions exist or the conveyor is abnormally long or complex and exceeds the chain pull capacity of one drive, a progressive chain pull computation is necessary where the friction losses are progressively calculated and accumulated through the path along the conveyor. Trigonometry can provide the sine of any angle, but the following angles of slope are most used.  resultant plus 2% for the 90 curve. to 3 = 53.1 ft. x .4575 lbs./ft. to 4 = 13.6 ft. x .4575 lbs./ft. Distance traveled, or displacement, per a change in time is the definition of velocity, or speed and direction. Distance traveled (displacement) per a change in time is the definition of velocity (speed and direction). In Figure #2, a conveyor is shown identical to Figure #1 except for the addition of an incline and decline. In Figure #1 a simple system about 115'-0" long is shown with four horizontal curves. + 6.97 lbs. To arrive at this figure, it is necessary to add the lift load and the friction factors, expressed as a small percentage of the live load, which act as resistance to the progress of the conveyor.

resultant plus 2% for the 90 curve. to 3 = 53.1 ft. x .4575 lbs./ft. to 4 = 13.6 ft. x .4575 lbs./ft. Distance traveled, or displacement, per a change in time is the definition of velocity, or speed and direction. Distance traveled (displacement) per a change in time is the definition of velocity (speed and direction). In Figure #2, a conveyor is shown identical to Figure #1 except for the addition of an incline and decline. In Figure #1 a simple system about 115'-0" long is shown with four horizontal curves. + 6.97 lbs. To arrive at this figure, it is necessary to add the lift load and the friction factors, expressed as a small percentage of the live load, which act as resistance to the progress of the conveyor.  Count how many full rotations are made by the roller in one minute.

Count how many full rotations are made by the roller in one minute.  However, by knowing the value of the various factors, the total chain pull may be determined by the point to point accumulation method of calculation. The net vertical rise (in feet) will be considered the total lifting height of the conveyor. Jesse Randall studied mathematics and physics and works as an embedded electronics engineer, developing microcontroller firmware and digital interfaces.

However, by knowing the value of the various factors, the total chain pull may be determined by the point to point accumulation method of calculation. The net vertical rise (in feet) will be considered the total lifting height of the conveyor. Jesse Randall studied mathematics and physics and works as an embedded electronics engineer, developing microcontroller firmware and digital interfaces.  There are few, if any, short cuts in the process of determining the chain pull on an endless chain conveyor.

There are few, if any, short cuts in the process of determining the chain pull on an endless chain conveyor.  + 2% =, 2 + (6'-0 x 30 lbs./ft.) Online Store Terms and Warranty. @ 1.50% = 15 lbs. Measure the diameter of the rollers around which the conveyor belt is wrapped. 0 lbs.

+ 2% =, 2 + (6'-0 x 30 lbs./ft.) Online Store Terms and Warranty. @ 1.50% = 15 lbs. Measure the diameter of the rollers around which the conveyor belt is wrapped. 0 lbs.  Next, divide by 12 to arrive at 314 feet, then divide by 5,280, to convert to miles per hour, 12 inches = 1 foot and 5,280 feet = 1 mile. Pi is a dimensionless factor, meaning it does not matter whether inches, centimeters or any other units of measurement are used.

Next, divide by 12 to arrive at 314 feet, then divide by 5,280, to convert to miles per hour, 12 inches = 1 foot and 5,280 feet = 1 mile. Pi is a dimensionless factor, meaning it does not matter whether inches, centimeters or any other units of measurement are used.  We also share information about your use of our site with our social media, advertising, and analytics partners who may combine it with other information that you've provided or that we have collected from your use of our services. =. 0 Multiply the diameter of the roller by pi, 3.14159. to 2 = 8.1 ft. x 4575 lbs./ft. A.

We also share information about your use of our site with our social media, advertising, and analytics partners who may combine it with other information that you've provided or that we have collected from your use of our services. =. 0 Multiply the diameter of the roller by pi, 3.14159. to 2 = 8.1 ft. x 4575 lbs./ft. A.  Measure the revolutions per minute of the rollers.

Measure the revolutions per minute of the rollers.  E. Total of A, B, C, D = total live load on the conveyor system. + 2% =, 5 Introduction of inclines and declines in a system further complicates chain pull calculation by adding to the forces. Chain Pull, SHORT CUT METHOD OF CHAIN PULL CALCULATION (Approximation Only). chain pull. + 3.13 lbs. + 3.13 lbs.

E. Total of A, B, C, D = total live load on the conveyor system. + 2% =, 5 Introduction of inclines and declines in a system further complicates chain pull calculation by adding to the forces. Chain Pull, SHORT CUT METHOD OF CHAIN PULL CALCULATION (Approximation Only). chain pull. + 3.13 lbs. + 3.13 lbs.  We are a non-profit group that run this service to share documents. The speed at which the conveyor belt moves depends on the size of the rollers and their revolutions per minute. To calculate this force, determine the difference in elevation of all the vertical curves traveling upward in the system. We use cookies to personalize content and analyze traffic. The following formula provides a result of .45 pounds per foot. For example, a roller with a diameter of 2 inches, has a circumference of 2 x 3.14159 or 6.28 inches. About Us | Products | Services | Resources | Contact Us | Site Map + 6.97 lbs. Whether you need help solving quadratic equations, inspiration for the upcoming science fair or the latest update on a major storm, Sciencing is here to help. When the loads are spaced under 2'-0" on centers, the formula of the total pounds per foot multiplied by the rise in feet can be used to determine the additional force in pounds for the inclined section. The lift load is the amount of force required to pull the live load upward along the vertical curves in the entire system. + 2% =, 4 to 1 = 11 ft. x .4575 lbs./ft. To keep our site running, we need your help to cover our server cost (about $500/m), a small donation will help us a lot. to 0 = 33.8 ft. x .4575 lbs./ft. =, 1 Get product updates and company news delivered directly to your inbox. B. per foot (including chain @ 2.5 lbs. chain pull.

We are a non-profit group that run this service to share documents. The speed at which the conveyor belt moves depends on the size of the rollers and their revolutions per minute. To calculate this force, determine the difference in elevation of all the vertical curves traveling upward in the system. We use cookies to personalize content and analyze traffic. The following formula provides a result of .45 pounds per foot. For example, a roller with a diameter of 2 inches, has a circumference of 2 x 3.14159 or 6.28 inches. About Us | Products | Services | Resources | Contact Us | Site Map + 6.97 lbs. Whether you need help solving quadratic equations, inspiration for the upcoming science fair or the latest update on a major storm, Sciencing is here to help. When the loads are spaced under 2'-0" on centers, the formula of the total pounds per foot multiplied by the rise in feet can be used to determine the additional force in pounds for the inclined section. The lift load is the amount of force required to pull the live load upward along the vertical curves in the entire system. + 2% =, 4 to 1 = 11 ft. x .4575 lbs./ft. To keep our site running, we need your help to cover our server cost (about $500/m), a small donation will help us a lot. to 0 = 33.8 ft. x .4575 lbs./ft. =, 1 Get product updates and company news delivered directly to your inbox. B. per foot (including chain @ 2.5 lbs. chain pull.  per foot) x 100'-0" or 1000 lbs. Manufacturers and grocery stores typically use conveyors to move products along a specific path. Speak With A Sparks Representative For Help With Your Conveyor Belt Calculations. A. Many factors, which vary greatly from system to system, influence the end result. Next, divide by 12, then divide by 5,280, to convert to miles per hour (12 inches = 1 foot and 5,280 feet = 1 mile). Objects and materials placed on top of the conveyor belt will be moved from one edge to the other as the rollers spin. "WE SERVICE WHAT WE SELL" In systems having multiple rises and falls, this may be treated somewhat differently, depending on loading patterns. Please copy and paste this embed script to where you want to embed. Due to the elevations changes, the formula for finding the pounds per foot chain pull is arranged differently because it must be assumed that at some point the incline will be loaded and the decline empty. Product carrier weight, product weight, coefficient of friction, track curves, inclines, declines, temperature and lubrication are some of the principle items affecting chain pull.

per foot) x 100'-0" or 1000 lbs. Manufacturers and grocery stores typically use conveyors to move products along a specific path. Speak With A Sparks Representative For Help With Your Conveyor Belt Calculations. A. Many factors, which vary greatly from system to system, influence the end result. Next, divide by 12, then divide by 5,280, to convert to miles per hour (12 inches = 1 foot and 5,280 feet = 1 mile). Objects and materials placed on top of the conveyor belt will be moved from one edge to the other as the rollers spin. "WE SERVICE WHAT WE SELL" In systems having multiple rises and falls, this may be treated somewhat differently, depending on loading patterns. Please copy and paste this embed script to where you want to embed. Due to the elevations changes, the formula for finding the pounds per foot chain pull is arranged differently because it must be assumed that at some point the incline will be loaded and the decline empty. Product carrier weight, product weight, coefficient of friction, track curves, inclines, declines, temperature and lubrication are some of the principle items affecting chain pull.

It will be seen that straight conveyor has a friction factor of 1.50%. Design Data - Step 4: Chain Pull Calculation. He has been writing on technology-related subjects since 2000. to 6 = 8.1 ft. x .4575 lbs./ft.

It will be seen that straight conveyor has a friction factor of 1.50%. Design Data - Step 4: Chain Pull Calculation. He has been writing on technology-related subjects since 2000. to 6 = 8.1 ft. x .4575 lbs./ft.  Multiply one more time by 60 to arrive at the total inches traveled per hour which equals 3,768. + 2% =, 1 2022 Leaf Group Ltd. / Leaf Group Media, All Rights Reserved. Friction resistance is found in the bearings of the chain wheels, curves, and the drive unit itself.

Multiply one more time by 60 to arrive at the total inches traveled per hour which equals 3,768. + 2% =, 1 2022 Leaf Group Ltd. / Leaf Group Media, All Rights Reserved. Friction resistance is found in the bearings of the chain wheels, curves, and the drive unit itself.

This can be seen in the chain pull calculation for the conveyor in Figure #2 from point #3 to #4. and the 2% friction for the 90 curve is added. Multiply weight of the chain (3.0 lbs.)

This can be seen in the chain pull calculation for the conveyor in Figure #2 from point #3 to #4. and the 2% friction for the 90 curve is added. Multiply weight of the chain (3.0 lbs.)