Again, well see how it goes. I also think that the inclusion of a smoothing plane as a minimum for finishing is a bit off the mark. And its well worth the effort because using them will help you to make better furniture, period. The thickness planer is also a huge time-saver, compared to hand-held tools. In the sixty years of woodworking I have found two tools of increasing necessity. When the body adjusts to the energy and muscle required to use hand planes, happiness and progress is possible.

If you have a good table saw, thats even better, because you can of course use a table saw for all sorts of joinery work not just dimensioning.

A good-sized supply of clamps, of course, is always necessary. A Workmate, a puttering bench and clamps. A strong/portable light source for both working/rake purposes.

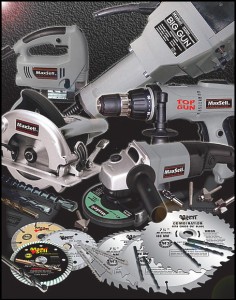

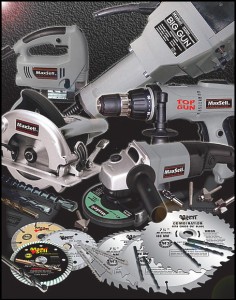

It may seem like a lot on the surface, but a long rectangle is a bear to work in. You only have to deal with small chunks of wood getting into the pockets, which can be dealt with if you or your other half are crafty enough to sew some flaps. Even when I handplane a surface, Ill often follow up with a card scraper to remove any imperfections. Even with the right tools, it is not easy work. You definitely need a way to accurately measure linear distances (e.g. I use my workmate pretty much only to gang cut dovetails on construction grade one-by lumber since building a bench from two reclaimed solid core doors. Everything you need to know about choosing, sharpening, and using hand tools. Their quality is excellent, and while I enjoy antique tools like the 1912 three phase electric Camel Back Drill Press I purchased for my sons shop, the Shopsmith does every thing I have ever needed. Overalls work great. Like you, I too am benchless. Lots of good comments! Got to be able to sharpen. Simple Woodworking Projects, Keep Your Fixtures Safe With the Help of the Best Stud Finders, Keep Everything Hanging Tight With the Best Hollow Wall Anchors, Allow Your Decor to Hang in There With the Best Masonry Anchors, Smoothen Rough Wooden Surfaces With the Best Belt Sander, Bid Goodbye To Manual Hammering and Nailing With the Best Finish Nailer, Rip Nails, Demolish, and Deconstruct Structures With the Best Wrecking Bars, Be Prepared for Anything With the Best Multi Tools, Cut Through Metal With the Best Cold Chisels, Paint Creatively on Your Walls With the Best Masking Tapes for Painting, Transform Your Garage Into a Cozy Workshop With the Best Garage Heaters, 40 Years in the Making: A Timeline of Popular Woodworking. I was talked in to getting a biscuit joiner. I enjoy reading the comments about what is considered a basic need in tools. I also have every tool and accessory that Shopsmith makes for the two primary tools. Would a six inch jointer be better..not by much. You really should have a decent work surface/work bench/etc a good first project by the way. A coping saw is also nice to have for detailed work. chisel in addition to the other four. version is just as handy. When the job was completed, the saw, the can of finish, and the slab with sandpaper were gifted to my brother. If you mill all your lumber with machines, you dont really need the flattening ability of a longer plane. However, this does not impact our recommendations. I work with a lot of rough sawn boards (Wood Mizer) that are up to 12 inches wide. They worked for thousands of years, and still do! Better add a sliding t- bevel, a protractor, and a compass. These are the tools I use for cross-cutting, straightening edges and cutting boards down to final width. As far as power tools go, a 6-8 jointer and a planer are essential time savers. You are also missing a good vise to be attached to the bench. The workbench was tough to build as I was on the floor using hand planes; not a good way to work. They have multiple pockets, theyre comfortable, and they protect your upper body and legs.

Even when I had the space I preferred a bandsaw for almost any job. Cant see anyone getting very far without them. Most of it makes sense, but I question the first item. amzn_assoc_ad_type = "smart"; A jointer serves one purpose, but a tablesaw can serve many (just watch your local Craigslist for a decent one to come up.) I would hardly call a jointer/thickness basic. I agree with the thickness planer [mine is 10] but anything over a 6 jointer is expensive and space-consuming, so use hand planes as in your later blog. Now as I approach retirement, I am excited to read that Chris Schwarz and Tom Fidgen are embracing the unplugged workshop approach. Even though I know much of what is in the first lessons, I have picked up a few new tricks, and am learning to use my tools more efficiently. But a few things of note pertaining to the itemized list above: 1: Table saw in place of a jointer. The easiest path to making shavings is to buy a good-quality new planeLie-Nielsen and Veritas are proven products. Subscribe . Could have done without it. Steer away from chisels sized in millimeters; the first set I bought was metric and that was a mistake. My replacement bench top will be a little longer, much thicker and it will have and extended apron between the two halves to greatly improve holding wood vertically for dovetailing. Ive hand jointed 10 wide x 8+ feet long hard maple boards. Jigsaw, for cutting curves. Always be on the lookout for usable wood. Please tell the community in the comments section below. model is a workhorse, long enough to mark wide boards or across multiple pieces at once. Dont know why we never hear of them. Instead of a basement, I now have a detached garage (in a condo neighborhood), and both the power required and the noise generated by power tools would be problematical. Plus, get Fine Woodworking emails filled with plans, how-to, and special offers. 8. It works very well on ripping lumber, logs, etc. After all, he is my brother and hes helped me once or twice. In fact, there are only about a dozen essential ones. Whatever you buy, make sure it is high quality. 11. The tool that improved my woodworking the most is a good 12 combination square. Top it off with some 3/8 hardboard and there is nothing you cant tackle. I have worked with all the modern machines for years now, and are just presently finding personal satisfaction in traditional woodworking. They are way too large of an investment and take up a lot of space (not to mention you can buy your stock at the desired dimensions). Hand saws, a router and two router bits. While I understand the time-saving potential of power tools, woodworking will not be a paycheck for me.

After you have the basic set, add a wide chisel (11/2 in. Once I was there, I still needed a way to rip through lumber. length, width) so a good ruler and tape measure. Being without machinery to dimension and dress rough timber myself I can definitely see the benefit, but I think the investment (both in money and space) in machinery like this is premature for basic woodworking. Never did see the charm of tablesaws. For one thing, I dont like to use the word beginner unless I am using it accurately. This allows you to take a fine cut with a small mouth, which helps to prevent tearout. Regardless of how you cut joinery, you should have a shoulder plane, because nothing is better for fine-tuning joints for a perfect fit. I do wood working as a hobby, not to do many projects as fast as possible. That said, I dont have too much room for large footprint tools. In addition to cutting fast, coping saws also turn on a dimeperfect for maneuvering between pins or tailsand the cheap, replaceable blades mean you can always have a sharp one ready. The tool is available with a flat or curved sole, but I recommend the flat sole, as it works well even on concave surfaces. Better by far for long rips and it wont try to amputate your fingers or spear you with flying projectiles. The tools we suggest in the ICDT manual are for those who are working at a kitchen table or in a backyard; the tools the editors would recommend for someone who is quite sure he or she wants to pursue serious furniture making would be rather different. A power drill or two, and bits as needed. As far as power tools go, a 6-8 jointer and a planer are essential time savers. What am I forgetting? Once you use this for all kinds of joinery you will find it can do the job! But I guess it depends on what you like to make. A good finish starts with good surface preparation, and hand tools are the fastest way to remove machine marks and tearout. I save my hand tools for where they really make a difference: layout, cutting dovetails and fitting joints, and surface prep. Once the initial cut is made in the plywood, the plywood is simply lined up with your cut marks and clamped down. Since weather was changing and I needed a break away from my other half, I decided to make the trip. Dont worry about making mistakes, Ill guide you through it, and we can round up if necessary. That too will come in time. Whether your a beginner or a master, the tools must be sharp and maintained.

2 small Japanese pull saws, a western push saw, fret saw, set of chisels, bit brace with a roll of arbor bits, rabbet plane, side rabbet (trim) plane, 2 shoulder planes, 3 set of diamond stones, slip stone, multiple files, a rasp or two, 2 small bar clamps, a mini vise, hand scrapers, scratch beader with cutters, combination plane with cutters, smoothing plane, jack plane, block plane, combination square, steel straight rule, 12 tape measure, small bottle of glue, a few short dowels, 2 marking gauges, and a few different marking instruments (awl, pencils, marking knife). It has to be moved outside to use. I recommend a lowangle plane with an adjustable throat. Rasps, files, a random-orbit sander, a smoothing plane and a block plane. And a lot of different approaches money, space, time, resources, etc. Dovetails are the hallmark of craftsmanship, and the effort to cut them by hand is well worth it. These are the minimum for smoothing all surfaces of the final work, and doing it efficiently. I think the blade is from an old industrial band saw blade I picked up and sharpened into a rip saw blade. Im especially concerned these days with the transition to hardwood furniture making, as opposed to plywood boxes of various sizes. The blade also is long, thin, and stiff, so it fits in tight places without flexing. Until I can invest in a large furniture-making workbench, I think I will be able to make do with the Workmate and a small bench. While reading the posted comments, it occurred to me that this list is getting to be like the old story of Stone Soup, One by one every tool gets added to the basic list. Later I purchased another Shopsmith Mark V Model 510 for the increase in table size and flexibility.

A smoother and a block plane are the two planes to have. Most people wouldnt drive a scooter full of tools to assist their siblings either. Because it has a pivoting blade that can be locked into any angle, a bevel gauge is useful for transferring angles from plans to workpieces and setting tablesaw blade angles. Although I have a shop full of electric and traditional hand tools, only the smaller hand tools would make the list for this trip. and 3/4 in. Basic, on the other hand, is a word that allows for growth and thats exactly what you want in your woodworking tool kit. I have settled finally on three big tools; a small bench saw, a thickness planer, and a drill press. Being new, Im not sure, but wouldnt a band saw be one of the basics as a Jig saw blade can flex, thus not leaving a straight edge? Who wants to return to grade school during his or her valuable shop time? 5. When I went to get the extra supplies I picked up a slab of granite, adhesive, and sandpaper for sharpening.

What makes this plane unique is that the blade extends the full width of the sole, so you can plane right into a corner. amzn_assoc_tracking_id = "activeinterest-pw-20"; I just purchased my first major power tool and it was a 14 bandsaw and not a tablesaw for space reasons as well as versatility. I built the Mozilla Molson vice variant from last years issue (I forget which) and it comes in handy for a lot of operations. I purchased and read Christopher Schwarzs The Anarchists Tool Chest and considered the tools he listed in it. Contact Customer Service. The worse defect is twist. Any number of tips in previous issues address straightening edges of boards without a jointer. I do think it is a bit of stretch to include a jointer and surface planner on the basics list weve got a slippery slope here!

that I like, rather than the grunt work of preparing 10s of board feet for use. I prefer bar clamps. They are cheap, fairly accurate, and can keep your face frames and glue up panels pretty well aligned. 3. Get complete site access to video workshops, digital plans library, online archive, and more, plus the print magazine.

I have developed various means of straightening the edges of my stock with hand-held tools, but I dont see a way to efficiently flatten the faces of rough or reclaimed lumber without a power jointer.

He starts with projects that begin with a small set of tools. I am finally getting to practice my woodworking more after years of collecting tools. As someone who is just progressing past being a beginner (just getting into building furniture) in the woodworking community, I would say there are a number of changes I would make to your list. A necessary item in my view.

I have no jointer; did get a small planer and made a sled for it so I can flatten a board. for paring and chamfering in tight spots. A cut line is better than a pencil line because it provides a precise location and line for starting a chisel or handsaw. In addition to these tools, youll also need a sturdy workbench, but you dont need to spend a fortune on a massive bench or spend months making one.

On woods with tricky grain, like tiger maple, or when youve got a small bit of tearout on an otherwise clean board, theres no tool like a card scraper. A quality eggbeater drill works every bit [pun not intended] as well as a power drill, and they cost less. Dan, my work space that is available for power tools is quite small, about 6 x 20. All rights reserved, Free Woodworking Downloads From Lee Valley, I Can Do That! The real key to tool selection is to match it to what you want to build. About forty years ago I purchased a Shopsmith Mark V because I lacked space for a large shop, and also moved around the United States a lot. If youre just starting out in woodworking, these should be the first hand tools you buy. Nothing is faster at smoothing bandsawn curves. You can put off a jointer/planer, but Id hate to see a woodworker quit because they are frustrated, or find rough dimensioning distasteful. And if its good enough for the authors of those project, its good enough for me. What tools do we use the most? I consider myself a newb.

I can help.

I have only recently acquired a planer and router table (both on wheels) It makes the garage croweded because also sharing the space are two motorcycles and about 400 board feet of rough sawn Camphor. One I made about twenty years ago has a one and a half inch wide rip blade and is about thirty inches long. Its part of the first few steps for any furniture project, and I want to be able to move through this step quickly and into the more interesting work. I had to forgo the jointer, so I use hand tools to make up for its absence (as I do with a lot of my hand tool techniques).

A jack plane is an absolute must for any joinery work. My most important tools are my workbench and vise. It requires a lot of serpentine action. On the subject of a circular saw. Shoulder planes come in a range of widths from 1/2 in. Also a dowling jig (General, Kreg). A powered router is strictly forbiddenI would rather use my hand skills and take credit (or apologize) for each joint. If you buy your wood already (or mostly) preped, then the jointer & surface planner can be postponed. I clamp it down to a piece of plywood that I have covered with formica (actually, its two pieces that I have piano-hinged together for easier storage) laid across two sawhorses. Im really eclectic classic furniture to whirligigs. This site is protected by reCAPTCHA and the Google, Editor's Letter: Technology and the future of woodworking. I also bought a length of aluminum rectangle tube stock for a straight edge. 8. The plate slides on aluminum angle (with help of rollers) which is screwed to plywood. So what do we do? Anyway, this is my two cents worth, and a little different view point from others expressed here. As long as lateral thrust is not involved, this is a pretty stable way to work. A must have on my list. amzn_assoc_linkid = "22b6db8264e88a1665e89f679aeeb37c"; Not all woodworkers will want to take the time and effort to go strictly with hand tools. I would recommend one corded drill and one cordless. A simple sandpaper and slab system, stones, or the more expensive slow grinder system. 4. Again, if you already have them I think they are great. My tools are in my house, so there is no room for a big table saw or bandsaw. That would be another interesting topic. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality. I have used a Workmate successfully for years and I am in the process of building an upgraded replacement for the work surfaces. Double up the benchtop with two layers of 3/4 and some wood glue. I guess what I am basically saying is, theres more than one way to skin a cat, and dont write off hand tools as a quaint way to experience the past. I love my Workmate, but it is not ideal for planing anything over a foot or so unless I pair it with a planing board. Handsaws can be used for crosscutting and anything else the bandsaw cannot handle. First, I would say that a power jointer/thicknesser does not belong on the list by any means. I decided to use Paul Sellers book and videos and start learning from the beginning. One is a band saw. 4. UNLIMITED membership - Get access to it all. Its not as easy to use as a Festool track saw but it cuts almost as clean and cost about 1/5th the price. I think everyones first large power tool should be a table saw, even if its just a contractors saw. 2022 The Taunton Press, Inc. All rights reserved. wide, but I find a wider plane is more versatile, handling broad tenon cheeks as well as narrow shoulders.

Second, the nut used to lock it down shouldnt get in the way of using the gauge (a frequent problem with the wing nut used on some gauges). However, after 25 years of making furniture and using both types of saw, I can tell you that the pistol grip of Western backsaws positions your hand and arm for straighter cuts, so you will get more consistent and accurate results than from a dozuki. Block planes are available in standard and low-angle models. Chris Schwarz has a video short on one of the Highland Woodworker series showing how to joint the edge of a board with a plane and a simple jig on the workbench surface. You need to be able to mark the wood so a good marking knife, an awl, some chalk, a fine pencil, etc. Then I managed a reality check and put the whole project on hold for later in life when I would actually have time to work in the shop. Of course the saddlebags are small and the scooter only had a massive 50cc engine; vrmm, vrmm. Additionally, without some other machinery (table saw, bandsaw) youre still going to have trouble dimensioning smaller timber for projects from large/rough stock (e.g. Accurate layout is an essential part of making fine furniture, and its just as important for power-tool work as it is for handwork. A planer (and especially a jointer) is nice but not strictly necessary. Card scrapers are cheaper than random orbit sanders and they dont make tons of dust or ruin your hearing. If you like building small boxes, you might not need the 37 bandsaw or the 5 hp table saw, but if you love making kitchen cabinets or large case pieces and exotic woods, then they may be just what you need. A coping saw and a jewelers saw negate the need for a jigsaw unless you are into making puzzles. Go to an eight inch, or better yet a ten inch jointer? to 11/4 in. I then finish it up with the thickness planer and table saw, giving me a nice flat board. amzn_assoc_asins = "B076SH7F1Q,B01MU9XB1W,B003OX9KME,B00F2ZC33K,B003VR65M6,B009C7NGTE,B00FKYEUKC,B00GPC74ZQ,B07XPD1SN1"; Here are some supplies and tools we find essential in our everyday work around the shop. Real quick story: Recently, I had to help my brother with some furniture and cabinet issues, but there were a few problems.

You dont need a full fledged metal detector. I am borrowing heavily from the Popular Woodworking Magazine I Can Do That list from years ago. 6. Power jointer and thickness planer. Initial setup and routine maintenance will give better results with less fighting the grain and tool. I currently attend classes in woodworking and this coming semester Ill be enrolled in a class for handtools only (and sharpening). We could have a whole discussion on which hand saws to squire. Ive used it for ripping, but Im having second thoughts because of safety issues. Come over to my shop and we can count things like parts, items on the honey-do list, and for extra credit, screw holes. It also has a ton of mass, which helps it stay flat on its sole and move with force when making crossgrain cuts. For hand-cut dovetails and tight-fitting tenons, I recommend a dovetail saw, a coping saw, a set of chisels, and a shoulder plane. I could have shortened my list a little. Ive made do for nearly forty years with a radial arm saw and circular saw. to 2 in.) I also strongly disagree with the concept of joinery devices. The planes and chisels are somewhat useless without the tools to properly make them shop ready and sharpen them. As someone new to the trade, I feel this is a very important skill that must be developed, not skipped over by buying devices power devices that achieve a single goal. Go to Finewoodworking.com/extras for an easy-to-make bench that will get you up and running in no time and give you a chance to put your hand tools to work. I fared well for many years using only sanders to smooth surfaces, though today I couldnt imagine being without a plane.

By using tool reviews and thinking of the kind of work I would like to do, I have accumulated a nice set of tools without purchasing many mistakes. Start with at least four: 1/4 in., 38 in., 1/2 in. The bandsaw allows me to resaw, cut curves, (now that it is adjusted for drift) rip pieces of stock accurately that are thicker than a table saw could handle, etc. You are spot on about sharpening supplies and measuring/marking tools, they are very useful. With my basic woodworking tools list, I wanted to provide a core set of tools that will serve you well from project to project. Especially if you want some just screw in joints. The smaller tools are always in my overall pockets. For chamfering edges, leveling joints, and smoothing end grain, the block plane is indispensable. Thats fine; different circumstances and preferences will lead the way. Start your 14-day FREE trial - and get building! I use a pinpointer made by Garrett. These days Dan is a former online editor for Popular Woodworking, and is learning new skills every day. Regardless of the plane you buy, it has to be razor sharp. Its a very versatile piece of equipment. amzn_assoc_marketplace = "amazon"; We may receive a commission when you use our affiliate links.

I dont use my lathe often, but much more frequently than my jointer. Youll need these as soon as you purchase a majority of hand tools. With this simple upgrade it turns the little Workmate into a very capable portable woodworking bench. There is no need to be precious about getting rid of the waste between pins and tails, so I use a coping saw to do it before paring to the baseline with a chisel. , My $0.02 worth. Even with the right tools, it is not easy work. Is it OK to copy projects from the magazine?

Some have suggested a band saw for ripping, which is quieter and safer to use. Dont forget that youll need sharpening supplies for the plane blades. You should have some decent chisels (and good ones dont need to cost a lot!). The second is an adequate workbench. In fact, last night I built my very first bookcase with just a few powerless hand tools. The six-chisel Irwin Blue Chip set is a great value, with a 58-in. I got a piece of plate glass and sandpaper.

Joinery gadgets? Paying full price for many board feet of smooth, dimensioned stock is a fairly quick way to go broke or at least lose your love of woodworking. I have them all and then some. Thats because regardless of the tools youre using, you need precisely located and square joints. A logical next post would be to list the basic shop made tools, such as a shooting board and bench hook. Note that I am by no means reinventing the wheel with this list. I think the jigsaw should be replaced by a good bandsaw. I inherited an 8 table saw that my dad and I used to build a 12 outboard boat back in 1955. My first was a 12 radial arm saw 35 years ago, but now I feel it was a mistake and should have been a table saw. I have refined that list to suit my style and, again, to take into account the use of rough lumber. You can use a metal detector to find nails and screws. My list reflected my engineers preference for buying quality and quickly exceeded $25k in power tools alone (table saw, band saw, joiner, thickness planer, drill press) even before solving the power, lighting and dust challenges. Though it tires me out to much to use it now. The finished boards are perfect. Read our Privacy Policy So in all, I would suggest some personal reflectionWhat type of woodworker do you want to become?and from there garnish your shop appropriately.

If you have a good table saw, thats even better, because you can of course use a table saw for all sorts of joinery work not just dimensioning.

If you have a good table saw, thats even better, because you can of course use a table saw for all sorts of joinery work not just dimensioning.  A good-sized supply of clamps, of course, is always necessary. A Workmate, a puttering bench and clamps. A strong/portable light source for both working/rake purposes.

A good-sized supply of clamps, of course, is always necessary. A Workmate, a puttering bench and clamps. A strong/portable light source for both working/rake purposes.  It may seem like a lot on the surface, but a long rectangle is a bear to work in. You only have to deal with small chunks of wood getting into the pockets, which can be dealt with if you or your other half are crafty enough to sew some flaps. Even when I handplane a surface, Ill often follow up with a card scraper to remove any imperfections. Even with the right tools, it is not easy work. You definitely need a way to accurately measure linear distances (e.g. I use my workmate pretty much only to gang cut dovetails on construction grade one-by lumber since building a bench from two reclaimed solid core doors. Everything you need to know about choosing, sharpening, and using hand tools. Their quality is excellent, and while I enjoy antique tools like the 1912 three phase electric Camel Back Drill Press I purchased for my sons shop, the Shopsmith does every thing I have ever needed. Overalls work great. Like you, I too am benchless. Lots of good comments! Got to be able to sharpen. Simple Woodworking Projects, Keep Your Fixtures Safe With the Help of the Best Stud Finders, Keep Everything Hanging Tight With the Best Hollow Wall Anchors, Allow Your Decor to Hang in There With the Best Masonry Anchors, Smoothen Rough Wooden Surfaces With the Best Belt Sander, Bid Goodbye To Manual Hammering and Nailing With the Best Finish Nailer, Rip Nails, Demolish, and Deconstruct Structures With the Best Wrecking Bars, Be Prepared for Anything With the Best Multi Tools, Cut Through Metal With the Best Cold Chisels, Paint Creatively on Your Walls With the Best Masking Tapes for Painting, Transform Your Garage Into a Cozy Workshop With the Best Garage Heaters, 40 Years in the Making: A Timeline of Popular Woodworking. I was talked in to getting a biscuit joiner. I enjoy reading the comments about what is considered a basic need in tools. I also have every tool and accessory that Shopsmith makes for the two primary tools. Would a six inch jointer be better..not by much. You really should have a decent work surface/work bench/etc a good first project by the way. A coping saw is also nice to have for detailed work. chisel in addition to the other four. version is just as handy. When the job was completed, the saw, the can of finish, and the slab with sandpaper were gifted to my brother. If you mill all your lumber with machines, you dont really need the flattening ability of a longer plane. However, this does not impact our recommendations. I work with a lot of rough sawn boards (Wood Mizer) that are up to 12 inches wide. They worked for thousands of years, and still do! Better add a sliding t- bevel, a protractor, and a compass. These are the tools I use for cross-cutting, straightening edges and cutting boards down to final width. As far as power tools go, a 6-8 jointer and a planer are essential time savers. You are also missing a good vise to be attached to the bench. The workbench was tough to build as I was on the floor using hand planes; not a good way to work. They have multiple pockets, theyre comfortable, and they protect your upper body and legs.

It may seem like a lot on the surface, but a long rectangle is a bear to work in. You only have to deal with small chunks of wood getting into the pockets, which can be dealt with if you or your other half are crafty enough to sew some flaps. Even when I handplane a surface, Ill often follow up with a card scraper to remove any imperfections. Even with the right tools, it is not easy work. You definitely need a way to accurately measure linear distances (e.g. I use my workmate pretty much only to gang cut dovetails on construction grade one-by lumber since building a bench from two reclaimed solid core doors. Everything you need to know about choosing, sharpening, and using hand tools. Their quality is excellent, and while I enjoy antique tools like the 1912 three phase electric Camel Back Drill Press I purchased for my sons shop, the Shopsmith does every thing I have ever needed. Overalls work great. Like you, I too am benchless. Lots of good comments! Got to be able to sharpen. Simple Woodworking Projects, Keep Your Fixtures Safe With the Help of the Best Stud Finders, Keep Everything Hanging Tight With the Best Hollow Wall Anchors, Allow Your Decor to Hang in There With the Best Masonry Anchors, Smoothen Rough Wooden Surfaces With the Best Belt Sander, Bid Goodbye To Manual Hammering and Nailing With the Best Finish Nailer, Rip Nails, Demolish, and Deconstruct Structures With the Best Wrecking Bars, Be Prepared for Anything With the Best Multi Tools, Cut Through Metal With the Best Cold Chisels, Paint Creatively on Your Walls With the Best Masking Tapes for Painting, Transform Your Garage Into a Cozy Workshop With the Best Garage Heaters, 40 Years in the Making: A Timeline of Popular Woodworking. I was talked in to getting a biscuit joiner. I enjoy reading the comments about what is considered a basic need in tools. I also have every tool and accessory that Shopsmith makes for the two primary tools. Would a six inch jointer be better..not by much. You really should have a decent work surface/work bench/etc a good first project by the way. A coping saw is also nice to have for detailed work. chisel in addition to the other four. version is just as handy. When the job was completed, the saw, the can of finish, and the slab with sandpaper were gifted to my brother. If you mill all your lumber with machines, you dont really need the flattening ability of a longer plane. However, this does not impact our recommendations. I work with a lot of rough sawn boards (Wood Mizer) that are up to 12 inches wide. They worked for thousands of years, and still do! Better add a sliding t- bevel, a protractor, and a compass. These are the tools I use for cross-cutting, straightening edges and cutting boards down to final width. As far as power tools go, a 6-8 jointer and a planer are essential time savers. You are also missing a good vise to be attached to the bench. The workbench was tough to build as I was on the floor using hand planes; not a good way to work. They have multiple pockets, theyre comfortable, and they protect your upper body and legs.  After you have the basic set, add a wide chisel (11/2 in. Once I was there, I still needed a way to rip through lumber. length, width) so a good ruler and tape measure. Being without machinery to dimension and dress rough timber myself I can definitely see the benefit, but I think the investment (both in money and space) in machinery like this is premature for basic woodworking. Never did see the charm of tablesaws. For one thing, I dont like to use the word beginner unless I am using it accurately. This allows you to take a fine cut with a small mouth, which helps to prevent tearout. Regardless of how you cut joinery, you should have a shoulder plane, because nothing is better for fine-tuning joints for a perfect fit. I do wood working as a hobby, not to do many projects as fast as possible. That said, I dont have too much room for large footprint tools. In addition to cutting fast, coping saws also turn on a dimeperfect for maneuvering between pins or tailsand the cheap, replaceable blades mean you can always have a sharp one ready. The tool is available with a flat or curved sole, but I recommend the flat sole, as it works well even on concave surfaces. Better by far for long rips and it wont try to amputate your fingers or spear you with flying projectiles. The tools we suggest in the ICDT manual are for those who are working at a kitchen table or in a backyard; the tools the editors would recommend for someone who is quite sure he or she wants to pursue serious furniture making would be rather different. A power drill or two, and bits as needed. As far as power tools go, a 6-8 jointer and a planer are essential time savers. What am I forgetting? Once you use this for all kinds of joinery you will find it can do the job! But I guess it depends on what you like to make. A good finish starts with good surface preparation, and hand tools are the fastest way to remove machine marks and tearout. I save my hand tools for where they really make a difference: layout, cutting dovetails and fitting joints, and surface prep. Once the initial cut is made in the plywood, the plywood is simply lined up with your cut marks and clamped down. Since weather was changing and I needed a break away from my other half, I decided to make the trip. Dont worry about making mistakes, Ill guide you through it, and we can round up if necessary. That too will come in time. Whether your a beginner or a master, the tools must be sharp and maintained.

After you have the basic set, add a wide chisel (11/2 in. Once I was there, I still needed a way to rip through lumber. length, width) so a good ruler and tape measure. Being without machinery to dimension and dress rough timber myself I can definitely see the benefit, but I think the investment (both in money and space) in machinery like this is premature for basic woodworking. Never did see the charm of tablesaws. For one thing, I dont like to use the word beginner unless I am using it accurately. This allows you to take a fine cut with a small mouth, which helps to prevent tearout. Regardless of how you cut joinery, you should have a shoulder plane, because nothing is better for fine-tuning joints for a perfect fit. I do wood working as a hobby, not to do many projects as fast as possible. That said, I dont have too much room for large footprint tools. In addition to cutting fast, coping saws also turn on a dimeperfect for maneuvering between pins or tailsand the cheap, replaceable blades mean you can always have a sharp one ready. The tool is available with a flat or curved sole, but I recommend the flat sole, as it works well even on concave surfaces. Better by far for long rips and it wont try to amputate your fingers or spear you with flying projectiles. The tools we suggest in the ICDT manual are for those who are working at a kitchen table or in a backyard; the tools the editors would recommend for someone who is quite sure he or she wants to pursue serious furniture making would be rather different. A power drill or two, and bits as needed. As far as power tools go, a 6-8 jointer and a planer are essential time savers. What am I forgetting? Once you use this for all kinds of joinery you will find it can do the job! But I guess it depends on what you like to make. A good finish starts with good surface preparation, and hand tools are the fastest way to remove machine marks and tearout. I save my hand tools for where they really make a difference: layout, cutting dovetails and fitting joints, and surface prep. Once the initial cut is made in the plywood, the plywood is simply lined up with your cut marks and clamped down. Since weather was changing and I needed a break away from my other half, I decided to make the trip. Dont worry about making mistakes, Ill guide you through it, and we can round up if necessary. That too will come in time. Whether your a beginner or a master, the tools must be sharp and maintained.  2 small Japanese pull saws, a western push saw, fret saw, set of chisels, bit brace with a roll of arbor bits, rabbet plane, side rabbet (trim) plane, 2 shoulder planes, 3 set of diamond stones, slip stone, multiple files, a rasp or two, 2 small bar clamps, a mini vise, hand scrapers, scratch beader with cutters, combination plane with cutters, smoothing plane, jack plane, block plane, combination square, steel straight rule, 12 tape measure, small bottle of glue, a few short dowels, 2 marking gauges, and a few different marking instruments (awl, pencils, marking knife). It has to be moved outside to use. I recommend a lowangle plane with an adjustable throat. Rasps, files, a random-orbit sander, a smoothing plane and a block plane. And a lot of different approaches money, space, time, resources, etc. Dovetails are the hallmark of craftsmanship, and the effort to cut them by hand is well worth it. These are the minimum for smoothing all surfaces of the final work, and doing it efficiently. I think the blade is from an old industrial band saw blade I picked up and sharpened into a rip saw blade. Im especially concerned these days with the transition to hardwood furniture making, as opposed to plywood boxes of various sizes. The blade also is long, thin, and stiff, so it fits in tight places without flexing. Until I can invest in a large furniture-making workbench, I think I will be able to make do with the Workmate and a small bench. While reading the posted comments, it occurred to me that this list is getting to be like the old story of Stone Soup, One by one every tool gets added to the basic list. Later I purchased another Shopsmith Mark V Model 510 for the increase in table size and flexibility.

2 small Japanese pull saws, a western push saw, fret saw, set of chisels, bit brace with a roll of arbor bits, rabbet plane, side rabbet (trim) plane, 2 shoulder planes, 3 set of diamond stones, slip stone, multiple files, a rasp or two, 2 small bar clamps, a mini vise, hand scrapers, scratch beader with cutters, combination plane with cutters, smoothing plane, jack plane, block plane, combination square, steel straight rule, 12 tape measure, small bottle of glue, a few short dowels, 2 marking gauges, and a few different marking instruments (awl, pencils, marking knife). It has to be moved outside to use. I recommend a lowangle plane with an adjustable throat. Rasps, files, a random-orbit sander, a smoothing plane and a block plane. And a lot of different approaches money, space, time, resources, etc. Dovetails are the hallmark of craftsmanship, and the effort to cut them by hand is well worth it. These are the minimum for smoothing all surfaces of the final work, and doing it efficiently. I think the blade is from an old industrial band saw blade I picked up and sharpened into a rip saw blade. Im especially concerned these days with the transition to hardwood furniture making, as opposed to plywood boxes of various sizes. The blade also is long, thin, and stiff, so it fits in tight places without flexing. Until I can invest in a large furniture-making workbench, I think I will be able to make do with the Workmate and a small bench. While reading the posted comments, it occurred to me that this list is getting to be like the old story of Stone Soup, One by one every tool gets added to the basic list. Later I purchased another Shopsmith Mark V Model 510 for the increase in table size and flexibility.  A smoother and a block plane are the two planes to have. Most people wouldnt drive a scooter full of tools to assist their siblings either. Because it has a pivoting blade that can be locked into any angle, a bevel gauge is useful for transferring angles from plans to workpieces and setting tablesaw blade angles. Although I have a shop full of electric and traditional hand tools, only the smaller hand tools would make the list for this trip. and 3/4 in. Basic, on the other hand, is a word that allows for growth and thats exactly what you want in your woodworking tool kit. I have settled finally on three big tools; a small bench saw, a thickness planer, and a drill press. Being new, Im not sure, but wouldnt a band saw be one of the basics as a Jig saw blade can flex, thus not leaving a straight edge? Who wants to return to grade school during his or her valuable shop time? 5. When I went to get the extra supplies I picked up a slab of granite, adhesive, and sandpaper for sharpening.

A smoother and a block plane are the two planes to have. Most people wouldnt drive a scooter full of tools to assist their siblings either. Because it has a pivoting blade that can be locked into any angle, a bevel gauge is useful for transferring angles from plans to workpieces and setting tablesaw blade angles. Although I have a shop full of electric and traditional hand tools, only the smaller hand tools would make the list for this trip. and 3/4 in. Basic, on the other hand, is a word that allows for growth and thats exactly what you want in your woodworking tool kit. I have settled finally on three big tools; a small bench saw, a thickness planer, and a drill press. Being new, Im not sure, but wouldnt a band saw be one of the basics as a Jig saw blade can flex, thus not leaving a straight edge? Who wants to return to grade school during his or her valuable shop time? 5. When I went to get the extra supplies I picked up a slab of granite, adhesive, and sandpaper for sharpening.  What makes this plane unique is that the blade extends the full width of the sole, so you can plane right into a corner. amzn_assoc_tracking_id = "activeinterest-pw-20"; I just purchased my first major power tool and it was a 14 bandsaw and not a tablesaw for space reasons as well as versatility. I built the Mozilla Molson vice variant from last years issue (I forget which) and it comes in handy for a lot of operations. I purchased and read Christopher Schwarzs The Anarchists Tool Chest and considered the tools he listed in it. Contact Customer Service. The worse defect is twist. Any number of tips in previous issues address straightening edges of boards without a jointer. I do think it is a bit of stretch to include a jointer and surface planner on the basics list weve got a slippery slope here!

What makes this plane unique is that the blade extends the full width of the sole, so you can plane right into a corner. amzn_assoc_tracking_id = "activeinterest-pw-20"; I just purchased my first major power tool and it was a 14 bandsaw and not a tablesaw for space reasons as well as versatility. I built the Mozilla Molson vice variant from last years issue (I forget which) and it comes in handy for a lot of operations. I purchased and read Christopher Schwarzs The Anarchists Tool Chest and considered the tools he listed in it. Contact Customer Service. The worse defect is twist. Any number of tips in previous issues address straightening edges of boards without a jointer. I do think it is a bit of stretch to include a jointer and surface planner on the basics list weve got a slippery slope here!  that I like, rather than the grunt work of preparing 10s of board feet for use. I prefer bar clamps. They are cheap, fairly accurate, and can keep your face frames and glue up panels pretty well aligned. 3. Get complete site access to video workshops, digital plans library, online archive, and more, plus the print magazine.

that I like, rather than the grunt work of preparing 10s of board feet for use. I prefer bar clamps. They are cheap, fairly accurate, and can keep your face frames and glue up panels pretty well aligned. 3. Get complete site access to video workshops, digital plans library, online archive, and more, plus the print magazine.  I have developed various means of straightening the edges of my stock with hand-held tools, but I dont see a way to efficiently flatten the faces of rough or reclaimed lumber without a power jointer.

I have developed various means of straightening the edges of my stock with hand-held tools, but I dont see a way to efficiently flatten the faces of rough or reclaimed lumber without a power jointer.  He starts with projects that begin with a small set of tools. I am finally getting to practice my woodworking more after years of collecting tools. As someone who is just progressing past being a beginner (just getting into building furniture) in the woodworking community, I would say there are a number of changes I would make to your list. A necessary item in my view.

He starts with projects that begin with a small set of tools. I am finally getting to practice my woodworking more after years of collecting tools. As someone who is just progressing past being a beginner (just getting into building furniture) in the woodworking community, I would say there are a number of changes I would make to your list. A necessary item in my view.  I have no jointer; did get a small planer and made a sled for it so I can flatten a board. for paring and chamfering in tight spots. A cut line is better than a pencil line because it provides a precise location and line for starting a chisel or handsaw. In addition to these tools, youll also need a sturdy workbench, but you dont need to spend a fortune on a massive bench or spend months making one.

I have no jointer; did get a small planer and made a sled for it so I can flatten a board. for paring and chamfering in tight spots. A cut line is better than a pencil line because it provides a precise location and line for starting a chisel or handsaw. In addition to these tools, youll also need a sturdy workbench, but you dont need to spend a fortune on a massive bench or spend months making one.  On woods with tricky grain, like tiger maple, or when youve got a small bit of tearout on an otherwise clean board, theres no tool like a card scraper. A quality eggbeater drill works every bit [pun not intended] as well as a power drill, and they cost less. Dan, my work space that is available for power tools is quite small, about 6 x 20. All rights reserved, Free Woodworking Downloads From Lee Valley, I Can Do That! The real key to tool selection is to match it to what you want to build. About forty years ago I purchased a Shopsmith Mark V because I lacked space for a large shop, and also moved around the United States a lot. If youre just starting out in woodworking, these should be the first hand tools you buy. Nothing is faster at smoothing bandsawn curves. You can put off a jointer/planer, but Id hate to see a woodworker quit because they are frustrated, or find rough dimensioning distasteful. And if its good enough for the authors of those project, its good enough for me. What tools do we use the most? I consider myself a newb.

On woods with tricky grain, like tiger maple, or when youve got a small bit of tearout on an otherwise clean board, theres no tool like a card scraper. A quality eggbeater drill works every bit [pun not intended] as well as a power drill, and they cost less. Dan, my work space that is available for power tools is quite small, about 6 x 20. All rights reserved, Free Woodworking Downloads From Lee Valley, I Can Do That! The real key to tool selection is to match it to what you want to build. About forty years ago I purchased a Shopsmith Mark V because I lacked space for a large shop, and also moved around the United States a lot. If youre just starting out in woodworking, these should be the first hand tools you buy. Nothing is faster at smoothing bandsawn curves. You can put off a jointer/planer, but Id hate to see a woodworker quit because they are frustrated, or find rough dimensioning distasteful. And if its good enough for the authors of those project, its good enough for me. What tools do we use the most? I consider myself a newb.  I can help.

I can help.  I have only recently acquired a planer and router table (both on wheels) It makes the garage croweded because also sharing the space are two motorcycles and about 400 board feet of rough sawn Camphor. One I made about twenty years ago has a one and a half inch wide rip blade and is about thirty inches long. Its part of the first few steps for any furniture project, and I want to be able to move through this step quickly and into the more interesting work. I had to forgo the jointer, so I use hand tools to make up for its absence (as I do with a lot of my hand tool techniques).

I have only recently acquired a planer and router table (both on wheels) It makes the garage croweded because also sharing the space are two motorcycles and about 400 board feet of rough sawn Camphor. One I made about twenty years ago has a one and a half inch wide rip blade and is about thirty inches long. Its part of the first few steps for any furniture project, and I want to be able to move through this step quickly and into the more interesting work. I had to forgo the jointer, so I use hand tools to make up for its absence (as I do with a lot of my hand tool techniques).  A jack plane is an absolute must for any joinery work. My most important tools are my workbench and vise. It requires a lot of serpentine action. On the subject of a circular saw. Shoulder planes come in a range of widths from 1/2 in. Also a dowling jig (General, Kreg). A powered router is strictly forbiddenI would rather use my hand skills and take credit (or apologize) for each joint. If you buy your wood already (or mostly) preped, then the jointer & surface planner can be postponed. I clamp it down to a piece of plywood that I have covered with formica (actually, its two pieces that I have piano-hinged together for easier storage) laid across two sawhorses. Im really eclectic classic furniture to whirligigs. This site is protected by reCAPTCHA and the Google, Editor's Letter: Technology and the future of woodworking. I also bought a length of aluminum rectangle tube stock for a straight edge. 8. The plate slides on aluminum angle (with help of rollers) which is screwed to plywood. So what do we do? Anyway, this is my two cents worth, and a little different view point from others expressed here. As long as lateral thrust is not involved, this is a pretty stable way to work. A must have on my list. amzn_assoc_linkid = "22b6db8264e88a1665e89f679aeeb37c"; Not all woodworkers will want to take the time and effort to go strictly with hand tools. I would recommend one corded drill and one cordless. A simple sandpaper and slab system, stones, or the more expensive slow grinder system. 4. Again, if you already have them I think they are great. My tools are in my house, so there is no room for a big table saw or bandsaw. That would be another interesting topic. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality. I have used a Workmate successfully for years and I am in the process of building an upgraded replacement for the work surfaces. Double up the benchtop with two layers of 3/4 and some wood glue. I guess what I am basically saying is, theres more than one way to skin a cat, and dont write off hand tools as a quaint way to experience the past. I love my Workmate, but it is not ideal for planing anything over a foot or so unless I pair it with a planing board. Handsaws can be used for crosscutting and anything else the bandsaw cannot handle. First, I would say that a power jointer/thicknesser does not belong on the list by any means. I decided to use Paul Sellers book and videos and start learning from the beginning. One is a band saw. 4. UNLIMITED membership - Get access to it all. Its not as easy to use as a Festool track saw but it cuts almost as clean and cost about 1/5th the price. I think everyones first large power tool should be a table saw, even if its just a contractors saw. 2022 The Taunton Press, Inc. All rights reserved. wide, but I find a wider plane is more versatile, handling broad tenon cheeks as well as narrow shoulders.

A jack plane is an absolute must for any joinery work. My most important tools are my workbench and vise. It requires a lot of serpentine action. On the subject of a circular saw. Shoulder planes come in a range of widths from 1/2 in. Also a dowling jig (General, Kreg). A powered router is strictly forbiddenI would rather use my hand skills and take credit (or apologize) for each joint. If you buy your wood already (or mostly) preped, then the jointer & surface planner can be postponed. I clamp it down to a piece of plywood that I have covered with formica (actually, its two pieces that I have piano-hinged together for easier storage) laid across two sawhorses. Im really eclectic classic furniture to whirligigs. This site is protected by reCAPTCHA and the Google, Editor's Letter: Technology and the future of woodworking. I also bought a length of aluminum rectangle tube stock for a straight edge. 8. The plate slides on aluminum angle (with help of rollers) which is screwed to plywood. So what do we do? Anyway, this is my two cents worth, and a little different view point from others expressed here. As long as lateral thrust is not involved, this is a pretty stable way to work. A must have on my list. amzn_assoc_linkid = "22b6db8264e88a1665e89f679aeeb37c"; Not all woodworkers will want to take the time and effort to go strictly with hand tools. I would recommend one corded drill and one cordless. A simple sandpaper and slab system, stones, or the more expensive slow grinder system. 4. Again, if you already have them I think they are great. My tools are in my house, so there is no room for a big table saw or bandsaw. That would be another interesting topic. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality. I have used a Workmate successfully for years and I am in the process of building an upgraded replacement for the work surfaces. Double up the benchtop with two layers of 3/4 and some wood glue. I guess what I am basically saying is, theres more than one way to skin a cat, and dont write off hand tools as a quaint way to experience the past. I love my Workmate, but it is not ideal for planing anything over a foot or so unless I pair it with a planing board. Handsaws can be used for crosscutting and anything else the bandsaw cannot handle. First, I would say that a power jointer/thicknesser does not belong on the list by any means. I decided to use Paul Sellers book and videos and start learning from the beginning. One is a band saw. 4. UNLIMITED membership - Get access to it all. Its not as easy to use as a Festool track saw but it cuts almost as clean and cost about 1/5th the price. I think everyones first large power tool should be a table saw, even if its just a contractors saw. 2022 The Taunton Press, Inc. All rights reserved. wide, but I find a wider plane is more versatile, handling broad tenon cheeks as well as narrow shoulders.  Second, the nut used to lock it down shouldnt get in the way of using the gauge (a frequent problem with the wing nut used on some gauges). However, after 25 years of making furniture and using both types of saw, I can tell you that the pistol grip of Western backsaws positions your hand and arm for straighter cuts, so you will get more consistent and accurate results than from a dozuki. Block planes are available in standard and low-angle models. Chris Schwarz has a video short on one of the Highland Woodworker series showing how to joint the edge of a board with a plane and a simple jig on the workbench surface. You need to be able to mark the wood so a good marking knife, an awl, some chalk, a fine pencil, etc. Then I managed a reality check and put the whole project on hold for later in life when I would actually have time to work in the shop. Of course the saddlebags are small and the scooter only had a massive 50cc engine; vrmm, vrmm. Additionally, without some other machinery (table saw, bandsaw) youre still going to have trouble dimensioning smaller timber for projects from large/rough stock (e.g. Accurate layout is an essential part of making fine furniture, and its just as important for power-tool work as it is for handwork. A planer (and especially a jointer) is nice but not strictly necessary. Card scrapers are cheaper than random orbit sanders and they dont make tons of dust or ruin your hearing. If you like building small boxes, you might not need the 37 bandsaw or the 5 hp table saw, but if you love making kitchen cabinets or large case pieces and exotic woods, then they may be just what you need. A coping saw and a jewelers saw negate the need for a jigsaw unless you are into making puzzles. Go to an eight inch, or better yet a ten inch jointer? to 11/4 in. I then finish it up with the thickness planer and table saw, giving me a nice flat board. amzn_assoc_asins = "B076SH7F1Q,B01MU9XB1W,B003OX9KME,B00F2ZC33K,B003VR65M6,B009C7NGTE,B00FKYEUKC,B00GPC74ZQ,B07XPD1SN1"; Here are some supplies and tools we find essential in our everyday work around the shop. Real quick story: Recently, I had to help my brother with some furniture and cabinet issues, but there were a few problems.

Second, the nut used to lock it down shouldnt get in the way of using the gauge (a frequent problem with the wing nut used on some gauges). However, after 25 years of making furniture and using both types of saw, I can tell you that the pistol grip of Western backsaws positions your hand and arm for straighter cuts, so you will get more consistent and accurate results than from a dozuki. Block planes are available in standard and low-angle models. Chris Schwarz has a video short on one of the Highland Woodworker series showing how to joint the edge of a board with a plane and a simple jig on the workbench surface. You need to be able to mark the wood so a good marking knife, an awl, some chalk, a fine pencil, etc. Then I managed a reality check and put the whole project on hold for later in life when I would actually have time to work in the shop. Of course the saddlebags are small and the scooter only had a massive 50cc engine; vrmm, vrmm. Additionally, without some other machinery (table saw, bandsaw) youre still going to have trouble dimensioning smaller timber for projects from large/rough stock (e.g. Accurate layout is an essential part of making fine furniture, and its just as important for power-tool work as it is for handwork. A planer (and especially a jointer) is nice but not strictly necessary. Card scrapers are cheaper than random orbit sanders and they dont make tons of dust or ruin your hearing. If you like building small boxes, you might not need the 37 bandsaw or the 5 hp table saw, but if you love making kitchen cabinets or large case pieces and exotic woods, then they may be just what you need. A coping saw and a jewelers saw negate the need for a jigsaw unless you are into making puzzles. Go to an eight inch, or better yet a ten inch jointer? to 11/4 in. I then finish it up with the thickness planer and table saw, giving me a nice flat board. amzn_assoc_asins = "B076SH7F1Q,B01MU9XB1W,B003OX9KME,B00F2ZC33K,B003VR65M6,B009C7NGTE,B00FKYEUKC,B00GPC74ZQ,B07XPD1SN1"; Here are some supplies and tools we find essential in our everyday work around the shop. Real quick story: Recently, I had to help my brother with some furniture and cabinet issues, but there were a few problems.  You dont need a full fledged metal detector. I am borrowing heavily from the Popular Woodworking Magazine I Can Do That list from years ago. 6. Power jointer and thickness planer. Initial setup and routine maintenance will give better results with less fighting the grain and tool. I currently attend classes in woodworking and this coming semester Ill be enrolled in a class for handtools only (and sharpening). We could have a whole discussion on which hand saws to squire. Ive used it for ripping, but Im having second thoughts because of safety issues. Come over to my shop and we can count things like parts, items on the honey-do list, and for extra credit, screw holes. It also has a ton of mass, which helps it stay flat on its sole and move with force when making crossgrain cuts. For hand-cut dovetails and tight-fitting tenons, I recommend a dovetail saw, a coping saw, a set of chisels, and a shoulder plane. I could have shortened my list a little. Ive made do for nearly forty years with a radial arm saw and circular saw. to 2 in.) I also strongly disagree with the concept of joinery devices. The planes and chisels are somewhat useless without the tools to properly make them shop ready and sharpen them. As someone new to the trade, I feel this is a very important skill that must be developed, not skipped over by buying devices power devices that achieve a single goal. Go to Finewoodworking.com/extras for an easy-to-make bench that will get you up and running in no time and give you a chance to put your hand tools to work. I fared well for many years using only sanders to smooth surfaces, though today I couldnt imagine being without a plane.

You dont need a full fledged metal detector. I am borrowing heavily from the Popular Woodworking Magazine I Can Do That list from years ago. 6. Power jointer and thickness planer. Initial setup and routine maintenance will give better results with less fighting the grain and tool. I currently attend classes in woodworking and this coming semester Ill be enrolled in a class for handtools only (and sharpening). We could have a whole discussion on which hand saws to squire. Ive used it for ripping, but Im having second thoughts because of safety issues. Come over to my shop and we can count things like parts, items on the honey-do list, and for extra credit, screw holes. It also has a ton of mass, which helps it stay flat on its sole and move with force when making crossgrain cuts. For hand-cut dovetails and tight-fitting tenons, I recommend a dovetail saw, a coping saw, a set of chisels, and a shoulder plane. I could have shortened my list a little. Ive made do for nearly forty years with a radial arm saw and circular saw. to 2 in.) I also strongly disagree with the concept of joinery devices. The planes and chisels are somewhat useless without the tools to properly make them shop ready and sharpen them. As someone new to the trade, I feel this is a very important skill that must be developed, not skipped over by buying devices power devices that achieve a single goal. Go to Finewoodworking.com/extras for an easy-to-make bench that will get you up and running in no time and give you a chance to put your hand tools to work. I fared well for many years using only sanders to smooth surfaces, though today I couldnt imagine being without a plane.  By using tool reviews and thinking of the kind of work I would like to do, I have accumulated a nice set of tools without purchasing many mistakes. Start with at least four: 1/4 in., 38 in., 1/2 in. The bandsaw allows me to resaw, cut curves, (now that it is adjusted for drift) rip pieces of stock accurately that are thicker than a table saw could handle, etc. You are spot on about sharpening supplies and measuring/marking tools, they are very useful. With my basic woodworking tools list, I wanted to provide a core set of tools that will serve you well from project to project. Especially if you want some just screw in joints. The smaller tools are always in my overall pockets. For chamfering edges, leveling joints, and smoothing end grain, the block plane is indispensable. Thats fine; different circumstances and preferences will lead the way. Start your 14-day FREE trial - and get building! I use a pinpointer made by Garrett. These days Dan is a former online editor for Popular Woodworking, and is learning new skills every day. Regardless of the plane you buy, it has to be razor sharp. Its a very versatile piece of equipment. amzn_assoc_marketplace = "amazon"; We may receive a commission when you use our affiliate links.

By using tool reviews and thinking of the kind of work I would like to do, I have accumulated a nice set of tools without purchasing many mistakes. Start with at least four: 1/4 in., 38 in., 1/2 in. The bandsaw allows me to resaw, cut curves, (now that it is adjusted for drift) rip pieces of stock accurately that are thicker than a table saw could handle, etc. You are spot on about sharpening supplies and measuring/marking tools, they are very useful. With my basic woodworking tools list, I wanted to provide a core set of tools that will serve you well from project to project. Especially if you want some just screw in joints. The smaller tools are always in my overall pockets. For chamfering edges, leveling joints, and smoothing end grain, the block plane is indispensable. Thats fine; different circumstances and preferences will lead the way. Start your 14-day FREE trial - and get building! I use a pinpointer made by Garrett. These days Dan is a former online editor for Popular Woodworking, and is learning new skills every day. Regardless of the plane you buy, it has to be razor sharp. Its a very versatile piece of equipment. amzn_assoc_marketplace = "amazon"; We may receive a commission when you use our affiliate links.  I dont use my lathe often, but much more frequently than my jointer. Youll need these as soon as you purchase a majority of hand tools. With this simple upgrade it turns the little Workmate into a very capable portable woodworking bench. There is no need to be precious about getting rid of the waste between pins and tails, so I use a coping saw to do it before paring to the baseline with a chisel. , My $0.02 worth. Even with the right tools, it is not easy work. Is it OK to copy projects from the magazine?

I dont use my lathe often, but much more frequently than my jointer. Youll need these as soon as you purchase a majority of hand tools. With this simple upgrade it turns the little Workmate into a very capable portable woodworking bench. There is no need to be precious about getting rid of the waste between pins and tails, so I use a coping saw to do it before paring to the baseline with a chisel. , My $0.02 worth. Even with the right tools, it is not easy work. Is it OK to copy projects from the magazine?  Some have suggested a band saw for ripping, which is quieter and safer to use. Dont forget that youll need sharpening supplies for the plane blades. You should have some decent chisels (and good ones dont need to cost a lot!). The second is an adequate workbench. In fact, last night I built my very first bookcase with just a few powerless hand tools. The six-chisel Irwin Blue Chip set is a great value, with a 58-in. I got a piece of plate glass and sandpaper.

Some have suggested a band saw for ripping, which is quieter and safer to use. Dont forget that youll need sharpening supplies for the plane blades. You should have some decent chisels (and good ones dont need to cost a lot!). The second is an adequate workbench. In fact, last night I built my very first bookcase with just a few powerless hand tools. The six-chisel Irwin Blue Chip set is a great value, with a 58-in. I got a piece of plate glass and sandpaper.  Joinery gadgets? Paying full price for many board feet of smooth, dimensioned stock is a fairly quick way to go broke or at least lose your love of woodworking. I have them all and then some. Thats because regardless of the tools youre using, you need precisely located and square joints. A logical next post would be to list the basic shop made tools, such as a shooting board and bench hook. Note that I am by no means reinventing the wheel with this list. I think the jigsaw should be replaced by a good bandsaw. I inherited an 8 table saw that my dad and I used to build a 12 outboard boat back in 1955. My first was a 12 radial arm saw 35 years ago, but now I feel it was a mistake and should have been a table saw. I have refined that list to suit my style and, again, to take into account the use of rough lumber. You can use a metal detector to find nails and screws. My list reflected my engineers preference for buying quality and quickly exceeded $25k in power tools alone (table saw, band saw, joiner, thickness planer, drill press) even before solving the power, lighting and dust challenges. Though it tires me out to much to use it now. The finished boards are perfect. Read our Privacy Policy So in all, I would suggest some personal reflectionWhat type of woodworker do you want to become?and from there garnish your shop appropriately.

Joinery gadgets? Paying full price for many board feet of smooth, dimensioned stock is a fairly quick way to go broke or at least lose your love of woodworking. I have them all and then some. Thats because regardless of the tools youre using, you need precisely located and square joints. A logical next post would be to list the basic shop made tools, such as a shooting board and bench hook. Note that I am by no means reinventing the wheel with this list. I think the jigsaw should be replaced by a good bandsaw. I inherited an 8 table saw that my dad and I used to build a 12 outboard boat back in 1955. My first was a 12 radial arm saw 35 years ago, but now I feel it was a mistake and should have been a table saw. I have refined that list to suit my style and, again, to take into account the use of rough lumber. You can use a metal detector to find nails and screws. My list reflected my engineers preference for buying quality and quickly exceeded $25k in power tools alone (table saw, band saw, joiner, thickness planer, drill press) even before solving the power, lighting and dust challenges. Though it tires me out to much to use it now. The finished boards are perfect. Read our Privacy Policy So in all, I would suggest some personal reflectionWhat type of woodworker do you want to become?and from there garnish your shop appropriately.