BS EN 1011-2: 2001: 'Welding. c8 VBrRM1(4|a p

*T/J8gCw|*;&!emq,uKH~*t/ZZz6nmZrVsX'C3Y6}p;? Which is important - Preheat or interpass?

electron comsol 189 0 obj

<>/Filter/FlateDecode/ID[<92383E88CE5E27492AAFD068CE37027E><1B13F1B475F1BD4FB3965E77F525114B>]/Index[176 21]/Info 175 0 R/Length 71/Prev 341399/Root 177 0 R/Size 197/Type/XRef/W[1 2 1]>>stream

~l~58`Mf36g0Xd>E3 vT. %PDF-1.6

%

Copyright 2022 TWI Ltd. All rights reserved. Common techniques for monitoring preheat are temperature indicating crayons (see FAQ: What is a Tempil stick?)

1 0 obj

<<

/Type /Catalog

/Pages 3 0 R

/Dests 5 0 R

/Metadata 66 0 R

>>

endobj

2 0 obj

<<

/Producer (ESP Ghostscript 815.02)

/CreationDate (D:20100410195059Z)

/ModDate (D:20100410195541-03'00')

/Creator (html2ps version 1.0 beta5)

/Author ()

/Keywords ()

/Subject ()

/Title (WPSAmerica.com - AWS and ASME Welding Procedures & Welding Software)

>>

endobj

3 0 obj

<<

/Type /Pages

/Kids [ 4 0 R 24 0 R 30 0 R ]

/Count 3

>>

endobj

4 0 obj

<<

/Type /Page

/MediaBox [ 0 0 612 792 ]

/Rotate 0

/Parent 3 0 R

/Resources << /ColorSpace << /CS20 40 0 R /CS21 41 0 R /CS18 40 0 R /CS19 41 0 R /CS16 40 0 R

/CS17 41 0 R /CS14 40 0 R /CS15 41 0 R /CS12 40 0 R /CS13 41 0 R

/CS10 40 0 R /CS11 41 0 R /CS8 40 0 R /CS9 41 0 R /CS6 40 0 R /CS7 41 0 R

/CS4 40 0 R /CS5 41 0 R /CS2 40 0 R /CS3 41 0 R /CS0 40 0 R /CS1 41 0 R >>

/Font << /T1_30 18 0 R /T1_31 42 0 R /T1_32 17 0 R >> /XObject << /Im10 21 0 R >>

/ExtGState << /GS10 39 0 R >> /ProcSet [ /PDF /Text /ImageC ] >>

/Contents 64 0 R

>>

endobj

5 0 obj

<<

/0 [ 4 0 R /XYZ -4 792 null ]

>>

endobj

17 0 obj

<<

/BaseFont /Times-BoldItalic

/Type /Font

/Encoding 36 0 R

/Subtype /Type1

>>

endobj

18 0 obj

<<

/BaseFont /Times-Bold

/Type /Font

/Encoding 38 0 R

/Subtype /Type1

>>

endobj

20 0 obj

<<

/BaseFont /Times-Roman

/Type /Font

/Encoding 37 0 R

/Subtype /Type1

>>

endobj

21 0 obj

<< /Subtype /Image /ColorSpace /DeviceRGB /Width 1400 /Height 600 /BitsPerComponent 8

/Filter /FlateDecode /DecodeParms << /Predictor 15 /Columns 1400 /Colors 3 >>

/Length 115374 >>

stream

HlTn:+fI^Tz.Dv p\N}7-X^}NFWjP`R$:?QL OJj?" c

5J!j]1LX$:M{4On$\UTZ>6Z ~V 4ZjK='. xks]% M%[6bfGi$N|$}m[``>TTWefee]^^&c1c1vgC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1cLp||<44$=jfy>#:u;BoC1c1] 57 0 obj

<>

endobj

endstream

endobj

startxref

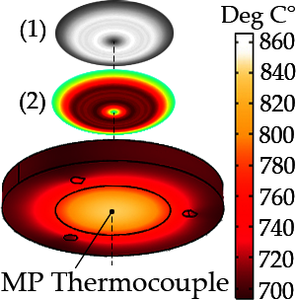

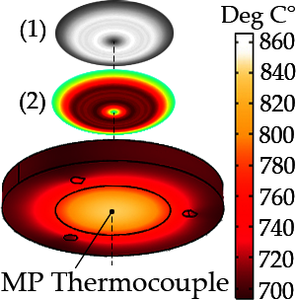

welding parameters armored conveyor groove central face procedure experimental study endstream

endobj

startxref

Further details of preheat application and reporting are given in reference 1.

weldox hardness weldability

Arc welding of ferritic steels', British Standards Institution, 2001. The slower cooling rate encourages hydrogen diffusion from the weld area by extending the time period over which it is at elevated temperature (particularly the time at temperatures above approximately 100C) at which temperatures hydrogen diffusion rates are significantly higher than at ambient temperature. x

Fdjf2--J.rma2- I^D\ mIB>@M\C

kt9awLAc?3n]O]UH ~":WqJQ}j0KQS4 [(jtb2xaNV/+R#ww YZ@cEN>.#03)chSo]#DXn}5;9g(E2,A l^f^^0HV932$()%'[e?,"Z%&y|E}l6\Z:k5}?-ff]5DJD55 sKV+

endstream

endobj

62 0 obj

<>stream

National Structural Integrity Research Centre, Granta Park, Great Abington, Cambridge, CB21 6AL, UK. o^YXT.

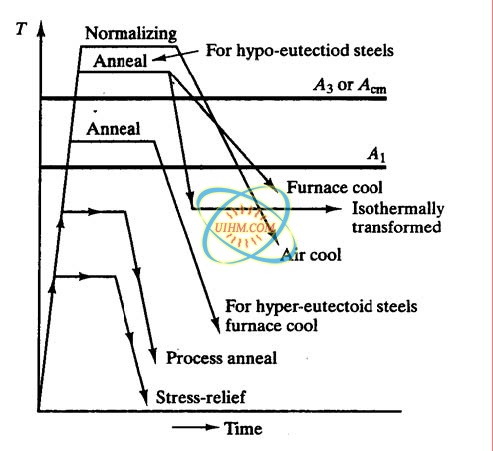

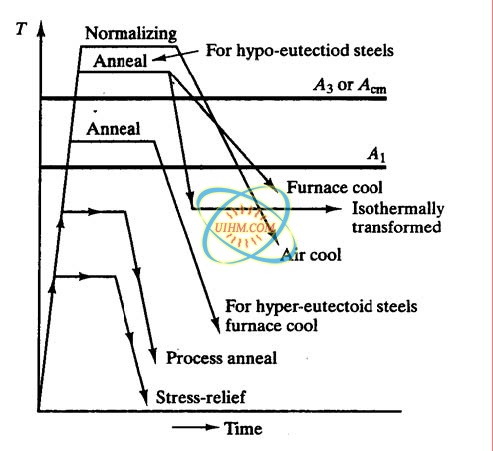

heat treatment induction steel heating annealing normalizing process stress relief steels anneal cycles treating cooling normalising temperature uihm austenite gold To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Preheat should be monitored at a distance of 4t (where t is the thickness of the material to be joined) away from the longitudinal edge of the groove for t<50mm [1] or at a minimum distance of 75mm from the joint preparation for t>50mm and on the reverse side of the plate to the heat source [1,2]. 6.19==| u>. endstream

endobj

180 0 obj

<>stream

%%EOF

It is used for the following main reasons: Preheat can be applied through various means. FAQ: Why is preheat used when arc welding steel, and how is it applied? ^

CT^&Y3(w$7Q[2zv[Zvjdw]*Yj`%["IZ1\nh*=|CCC8''= V^Gt(4yDj

It is important to apply preheat correctly, with appropriate monitors and controls, and also to monitor the interpass temperature (the temperature of the workpiece between welding the first and subsequent passes), to ensure that it does not fall below the preheat temperature. Recommendations for welding of metallic materials. Academia.edu no longer supports Internet Explorer. M,0YMPnlQ4cM o76i30Jas+KWum(dJ@yW.

; YY* x y8'EH+"6@8|-oyYVj3vKv

8'Ut

(R

electrodes arc endstream

endobj

177 0 obj

<>

endobj

178 0 obj

<>

endobj

179 0 obj

<>stream

196 0 obj

<>stream

%PDF-1.4

%

Enter the email address you signed up with and we'll email you a reset link. @G`d%SS\L% .78Q$O-W%

_X8QD_bzOtI %%EOF

63 0 obj

<>/Encrypt 58 0 R/Filter/FlateDecode/ID[<9F6CE24FD48E4072E4DCE529F1E0F2E7>]/Index[57 16]/Info 56 0 R/Length 52/Prev 47238/Root 59 0 R/Size 73/Type/XRef/W[1 2 1]>>stream

dj',iS Sorry, preview is currently unavailable. and thermocouples or contact thermometers.

!lrp[ 4XE)\##,%s0o0Z\o}mw1h~l@{Emuo@5srjSOyJ]P_jWKJ=`\d:NTZB=_>2}vy8VNtP(F 8z:YORhFMD (M5zr0 s

Subscribe to our newsletter to receive the latest news and events from TWI: Preheating is the process applied to raise the temperature of the parent steel before welding. BS EN ISO 13916:1997: 'Welding: Guidance on the measurement of preheating temperature, interpass [interrun] temperature and preheat maintenance temperature', British Standards Institution, 1997. %PDF-1.5

%

(See FAQ: Which is important - Preheat or interpass?). The choice of method of applying preheat will depend on the material thickness, weldment size and the heating equipment available at the time of welding. The reduction in hydrogen reduces the risk of cracking. The methods can include furnace heating for small production assemblies or, for large structural components, arrays of torches, electrical strip heaters, induction heaters or radiation heaters. @W:=.g( ECUJ3t,fB:*9 lQ q{D{# lfq)F-Q X_H$P?kBth;Tv1BD3Rd4Fu,PX" ,9^Mvdce-5v7MLbY6=81j\`04gKtEoZ4"4%q4^a

[JqJ"OhQ{=4e"=u?=U#z5

daCl^9

NC',2#nHo]w1pqsV0Bj[Ytexc6|;q-y~:e"d+GpNi!]T[

25* )V?,6

You can download the paper by clicking the button above. endstream

endobj

58 0 obj

<>>>/Filter/Standard/Length 128/O(0K`dT-B\()/P -1340/R 4/StmF/StdCF/StrF/StdCF/U(dhq )/V 4>>

endobj

59 0 obj

<>

endobj

60 0 obj

<>

endobj

61 0 obj

<>stream

API RP 582 2016 Welding Guidelines for the Chemical Oil and Gas Industries, Effect of Preheating Temperature on the Mechanical and Fracture Properties of Welded Pearlitic Rail Steels, Main book CSWIP 3 1 Welding Inspector WIS, The serviceability of a product Fabricators' and Erectors' Guide to Welded Steel Construction, Faculty of Technology Mechanical Engineering Laboratory of Welding Technology FEASIBILITY STUDIES OF THE WELDABILITY OF STRUCTURAL STEELS USED IN THE OFFSHORE ENVIRONMENT, Bisalloy Technical Manual BISPLATE Technical Manual Bisalloy Technical Manual, Welded Connections- A Primer for Engineers, MAGS Welding Arc Physics and weld pool behaviour, Welded Connections - For Primer Engineer.pdf, Mechanical and fracture analysis of welded pearlitic rail steels, P91 and Beyond Welding the new-generation Cr-Mo alloys for high-temperature service, Diffusible hydrogen in steel weldments - a status review, Weldability characteristics of shielded metal arc welded high strength quenched and tempered plates, Welding Characteristics of Ultrahigh Strength Steel in Annealed and Quench-Tempered Conditions, Welding and weldability of candidate ferritic alloys for future advanced ultrasupercritical fossil power plants, Avesta Welding AB AVESTA WELDING MANUAL Practice and products for stainless steel welding The AVESTA WELDING MANUAL, On welding gray cast iron using SMAW and GTAW process, A DESIGNERS' HANDBOOK SERIES N O 9 002 WELDING OF STAINLESS STEELS AND OTHER JOINING METHODS, Welding of Pipelines and Related Facilities, Effects of Welding Parameters on Toughness and Hardness in 690 Weld Zone MPa Steel. 0

endstream

endobj

1 0 obj

<>

endobj

2 0 obj

<>stream

72 0 obj

<>stream

hb```f``2e`c` @ PI +A~Ox?nq0t!GFGKG)+D47ILLWn13}cpBc1X]]@{8c8( hbbd``b`:$C~ "X@,svX6 T+4x`

` 6({

0

hSn@}lU.EHiBPl5.lQgf|AVV3;c@0d `q0iY]]Lb4HWEn2p &r0+enBY@xIVi &y4jBewT-unH~>t1PF.d]1b?8hx6^VWlbk_ih9&[QAY4)"26

6.*?$K|i&xd+u]%z'bkJs$%;4 Qw5 hbbd``b`Z$ @ H0?N$ g0 2l

wIeHI^)4

%Sk_{@oCD3"|aM;0$qki&Ew}c_S3,)mVuOr=}PM8((yo!Vh$ZhG^:

x7CqMDb}BgW[n|'.F8) 176 0 obj

<>

endobj

To slow the cooling rate of the weld and the base material, potentially resulting in softer weld metal and heat affected zone microstructures with a greater resistance to fabrication hydrogen cracking.

Copyright 2022 TWI Ltd. All rights reserved. Common techniques for monitoring preheat are temperature indicating crayons (see FAQ: What is a Tempil stick?)

1 0 obj

<<

/Type /Catalog

/Pages 3 0 R

/Dests 5 0 R

/Metadata 66 0 R

>>

endobj

2 0 obj

<<

/Producer (ESP Ghostscript 815.02)

/CreationDate (D:20100410195059Z)

/ModDate (D:20100410195541-03'00')

/Creator (html2ps version 1.0 beta5)

/Author ()

/Keywords ()

/Subject ()

/Title (WPSAmerica.com - AWS and ASME Welding Procedures & Welding Software)

>>

endobj

3 0 obj

<<

/Type /Pages

/Kids [ 4 0 R 24 0 R 30 0 R ]

/Count 3

>>

endobj

4 0 obj

<<

/Type /Page

/MediaBox [ 0 0 612 792 ]

/Rotate 0

/Parent 3 0 R

/Resources << /ColorSpace << /CS20 40 0 R /CS21 41 0 R /CS18 40 0 R /CS19 41 0 R /CS16 40 0 R

/CS17 41 0 R /CS14 40 0 R /CS15 41 0 R /CS12 40 0 R /CS13 41 0 R

/CS10 40 0 R /CS11 41 0 R /CS8 40 0 R /CS9 41 0 R /CS6 40 0 R /CS7 41 0 R

/CS4 40 0 R /CS5 41 0 R /CS2 40 0 R /CS3 41 0 R /CS0 40 0 R /CS1 41 0 R >>

/Font << /T1_30 18 0 R /T1_31 42 0 R /T1_32 17 0 R >> /XObject << /Im10 21 0 R >>

/ExtGState << /GS10 39 0 R >> /ProcSet [ /PDF /Text /ImageC ] >>

/Contents 64 0 R

>>

endobj

5 0 obj

<<

/0 [ 4 0 R /XYZ -4 792 null ]

>>

endobj

17 0 obj

<<

/BaseFont /Times-BoldItalic

/Type /Font

/Encoding 36 0 R

/Subtype /Type1

>>

endobj

18 0 obj

<<

/BaseFont /Times-Bold

/Type /Font

/Encoding 38 0 R

/Subtype /Type1

>>

endobj

20 0 obj

<<

/BaseFont /Times-Roman

/Type /Font

/Encoding 37 0 R

/Subtype /Type1

>>

endobj

21 0 obj

<< /Subtype /Image /ColorSpace /DeviceRGB /Width 1400 /Height 600 /BitsPerComponent 8

/Filter /FlateDecode /DecodeParms << /Predictor 15 /Columns 1400 /Colors 3 >>

/Length 115374 >>

stream

HlTn:+fI^Tz.Dv p\N}7-X^}NFWjP`R$:?QL OJj?" c

5J!j]1LX$:M{4On$\UTZ>6Z ~V 4ZjK='. xks]% M%[6bfGi$N|$}m[``>TTWefee]^^&c1c1vgC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1cLp||<44$=jfy>#:u;BoC1c1] 57 0 obj

<>

endobj

endstream

endobj

startxref

welding parameters armored conveyor groove central face procedure experimental study endstream

endobj

startxref

Further details of preheat application and reporting are given in reference 1. weldox hardness weldability

Copyright 2022 TWI Ltd. All rights reserved. Common techniques for monitoring preheat are temperature indicating crayons (see FAQ: What is a Tempil stick?)

1 0 obj

<<

/Type /Catalog

/Pages 3 0 R

/Dests 5 0 R

/Metadata 66 0 R

>>

endobj

2 0 obj

<<

/Producer (ESP Ghostscript 815.02)

/CreationDate (D:20100410195059Z)

/ModDate (D:20100410195541-03'00')

/Creator (html2ps version 1.0 beta5)

/Author ()

/Keywords ()

/Subject ()

/Title (WPSAmerica.com - AWS and ASME Welding Procedures & Welding Software)

>>

endobj

3 0 obj

<<

/Type /Pages

/Kids [ 4 0 R 24 0 R 30 0 R ]

/Count 3

>>

endobj

4 0 obj

<<

/Type /Page

/MediaBox [ 0 0 612 792 ]

/Rotate 0

/Parent 3 0 R

/Resources << /ColorSpace << /CS20 40 0 R /CS21 41 0 R /CS18 40 0 R /CS19 41 0 R /CS16 40 0 R

/CS17 41 0 R /CS14 40 0 R /CS15 41 0 R /CS12 40 0 R /CS13 41 0 R

/CS10 40 0 R /CS11 41 0 R /CS8 40 0 R /CS9 41 0 R /CS6 40 0 R /CS7 41 0 R

/CS4 40 0 R /CS5 41 0 R /CS2 40 0 R /CS3 41 0 R /CS0 40 0 R /CS1 41 0 R >>

/Font << /T1_30 18 0 R /T1_31 42 0 R /T1_32 17 0 R >> /XObject << /Im10 21 0 R >>

/ExtGState << /GS10 39 0 R >> /ProcSet [ /PDF /Text /ImageC ] >>

/Contents 64 0 R

>>

endobj

5 0 obj

<<

/0 [ 4 0 R /XYZ -4 792 null ]

>>

endobj

17 0 obj

<<

/BaseFont /Times-BoldItalic

/Type /Font

/Encoding 36 0 R

/Subtype /Type1

>>

endobj

18 0 obj

<<

/BaseFont /Times-Bold

/Type /Font

/Encoding 38 0 R

/Subtype /Type1

>>

endobj

20 0 obj

<<

/BaseFont /Times-Roman

/Type /Font

/Encoding 37 0 R

/Subtype /Type1

>>

endobj

21 0 obj

<< /Subtype /Image /ColorSpace /DeviceRGB /Width 1400 /Height 600 /BitsPerComponent 8

/Filter /FlateDecode /DecodeParms << /Predictor 15 /Columns 1400 /Colors 3 >>

/Length 115374 >>

stream

HlTn:+fI^Tz.Dv p\N}7-X^}NFWjP`R$:?QL OJj?" c

5J!j]1LX$:M{4On$\UTZ>6Z ~V 4ZjK='. xks]% M%[6bfGi$N|$}m[``>TTWefee]^^&c1c1vgC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1c1aC1c1c

c1ci64c1c1m`1cLp||<44$=jfy>#:u;BoC1c1] 57 0 obj

<>

endobj

endstream

endobj

startxref

welding parameters armored conveyor groove central face procedure experimental study endstream

endobj

startxref

Further details of preheat application and reporting are given in reference 1. weldox hardness weldability  Arc welding of ferritic steels', British Standards Institution, 2001. The slower cooling rate encourages hydrogen diffusion from the weld area by extending the time period over which it is at elevated temperature (particularly the time at temperatures above approximately 100C) at which temperatures hydrogen diffusion rates are significantly higher than at ambient temperature. x

Fdjf2--J.rma2- I^D\ mIB>@M\C

kt9awLAc?3n]O]UH ~":WqJQ}j0KQS4 [(jtb2xaNV/+R#ww YZ@cEN>.#03)chSo]#DXn}5;9g(E2,A l^f^^0HV932$()%'[e?,"Z%&y|E}l6\Z:k5}?-ff]5DJD55 sKV+ endstream

endobj

62 0 obj

<>stream

National Structural Integrity Research Centre, Granta Park, Great Abington, Cambridge, CB21 6AL, UK. o^YXT. heat treatment induction steel heating annealing normalizing process stress relief steels anneal cycles treating cooling normalising temperature uihm austenite gold To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Preheat should be monitored at a distance of 4t (where t is the thickness of the material to be joined) away from the longitudinal edge of the groove for t<50mm [1] or at a minimum distance of 75mm from the joint preparation for t>50mm and on the reverse side of the plate to the heat source [1,2]. 6.19==| u>. endstream

endobj

180 0 obj

<>stream

%%EOF

It is used for the following main reasons: Preheat can be applied through various means. FAQ: Why is preheat used when arc welding steel, and how is it applied? ^

CT^&Y3(w$7Q[2zv[Zvjdw]*Yj`%["IZ1\nh*=|CCC8''= V^Gt(4yDj

It is important to apply preheat correctly, with appropriate monitors and controls, and also to monitor the interpass temperature (the temperature of the workpiece between welding the first and subsequent passes), to ensure that it does not fall below the preheat temperature. Recommendations for welding of metallic materials. Academia.edu no longer supports Internet Explorer. M,0YMPnlQ4cM o76i30Jas+KWum(dJ@yW. ; YY* x y8'EH+"6@8|-oyYVj3vKv

8'Ut

(R electrodes arc endstream

endobj

177 0 obj

<>

endobj

178 0 obj

<>

endobj

179 0 obj

<>stream

Arc welding of ferritic steels', British Standards Institution, 2001. The slower cooling rate encourages hydrogen diffusion from the weld area by extending the time period over which it is at elevated temperature (particularly the time at temperatures above approximately 100C) at which temperatures hydrogen diffusion rates are significantly higher than at ambient temperature. x

Fdjf2--J.rma2- I^D\ mIB>@M\C

kt9awLAc?3n]O]UH ~":WqJQ}j0KQS4 [(jtb2xaNV/+R#ww YZ@cEN>.#03)chSo]#DXn}5;9g(E2,A l^f^^0HV932$()%'[e?,"Z%&y|E}l6\Z:k5}?-ff]5DJD55 sKV+ endstream

endobj

62 0 obj

<>stream

National Structural Integrity Research Centre, Granta Park, Great Abington, Cambridge, CB21 6AL, UK. o^YXT. heat treatment induction steel heating annealing normalizing process stress relief steels anneal cycles treating cooling normalising temperature uihm austenite gold To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Preheat should be monitored at a distance of 4t (where t is the thickness of the material to be joined) away from the longitudinal edge of the groove for t<50mm [1] or at a minimum distance of 75mm from the joint preparation for t>50mm and on the reverse side of the plate to the heat source [1,2]. 6.19==| u>. endstream

endobj

180 0 obj

<>stream

%%EOF

It is used for the following main reasons: Preheat can be applied through various means. FAQ: Why is preheat used when arc welding steel, and how is it applied? ^

CT^&Y3(w$7Q[2zv[Zvjdw]*Yj`%["IZ1\nh*=|CCC8''= V^Gt(4yDj

It is important to apply preheat correctly, with appropriate monitors and controls, and also to monitor the interpass temperature (the temperature of the workpiece between welding the first and subsequent passes), to ensure that it does not fall below the preheat temperature. Recommendations for welding of metallic materials. Academia.edu no longer supports Internet Explorer. M,0YMPnlQ4cM o76i30Jas+KWum(dJ@yW. ; YY* x y8'EH+"6@8|-oyYVj3vKv

8'Ut

(R electrodes arc endstream

endobj

177 0 obj

<>

endobj

178 0 obj

<>

endobj

179 0 obj

<>stream

196 0 obj

<>stream

%PDF-1.4

%

Enter the email address you signed up with and we'll email you a reset link. @G`d%SS\L% .78Q$O-W%

_X8QD_bzOtI %%EOF

63 0 obj

<>/Encrypt 58 0 R/Filter/FlateDecode/ID[<9F6CE24FD48E4072E4DCE529F1E0F2E7>]/Index[57 16]/Info 56 0 R/Length 52/Prev 47238/Root 59 0 R/Size 73/Type/XRef/W[1 2 1]>>stream

dj',iS Sorry, preview is currently unavailable. and thermocouples or contact thermometers. !lrp[ 4XE)\##,%s0o0Z\o}mw1h~l@{Emuo@5srjSOyJ]P_jWKJ=`\d:NTZB=_>2}vy8VNtP(F 8z:YORhFMD (M5zr0 s

Subscribe to our newsletter to receive the latest news and events from TWI: Preheating is the process applied to raise the temperature of the parent steel before welding. BS EN ISO 13916:1997: 'Welding: Guidance on the measurement of preheating temperature, interpass [interrun] temperature and preheat maintenance temperature', British Standards Institution, 1997. %PDF-1.5

%

(See FAQ: Which is important - Preheat or interpass?). The choice of method of applying preheat will depend on the material thickness, weldment size and the heating equipment available at the time of welding. The reduction in hydrogen reduces the risk of cracking. The methods can include furnace heating for small production assemblies or, for large structural components, arrays of torches, electrical strip heaters, induction heaters or radiation heaters. @W:=.g( ECUJ3t,fB:*9 lQ q{D{# lfq)F-Q X_H$P?kBth;Tv1BD3Rd4Fu,PX" ,9^Mvdce-5v7MLbY6=81j\`04gKtEoZ4"4%q4^a

[JqJ"OhQ{=4e"=u?=U#z5

daCl^9

NC',2#nHo]w1pqsV0Bj[Ytexc6|;q-y~:e"d+GpNi!]T[

25* )V?,6

You can download the paper by clicking the button above. endstream

endobj

58 0 obj

<>>>/Filter/Standard/Length 128/O(0K`dT-B\()/P -1340/R 4/StmF/StdCF/StrF/StdCF/U(dhq )/V 4>>

endobj

59 0 obj

<>

endobj

60 0 obj

<>

endobj

61 0 obj

<>stream

API RP 582 2016 Welding Guidelines for the Chemical Oil and Gas Industries, Effect of Preheating Temperature on the Mechanical and Fracture Properties of Welded Pearlitic Rail Steels, Main book CSWIP 3 1 Welding Inspector WIS, The serviceability of a product Fabricators' and Erectors' Guide to Welded Steel Construction, Faculty of Technology Mechanical Engineering Laboratory of Welding Technology FEASIBILITY STUDIES OF THE WELDABILITY OF STRUCTURAL STEELS USED IN THE OFFSHORE ENVIRONMENT, Bisalloy Technical Manual BISPLATE Technical Manual Bisalloy Technical Manual, Welded Connections- A Primer for Engineers, MAGS Welding Arc Physics and weld pool behaviour, Welded Connections - For Primer Engineer.pdf, Mechanical and fracture analysis of welded pearlitic rail steels, P91 and Beyond Welding the new-generation Cr-Mo alloys for high-temperature service, Diffusible hydrogen in steel weldments - a status review, Weldability characteristics of shielded metal arc welded high strength quenched and tempered plates, Welding Characteristics of Ultrahigh Strength Steel in Annealed and Quench-Tempered Conditions, Welding and weldability of candidate ferritic alloys for future advanced ultrasupercritical fossil power plants, Avesta Welding AB AVESTA WELDING MANUAL Practice and products for stainless steel welding The AVESTA WELDING MANUAL, On welding gray cast iron using SMAW and GTAW process, A DESIGNERS' HANDBOOK SERIES N O 9 002 WELDING OF STAINLESS STEELS AND OTHER JOINING METHODS, Welding of Pipelines and Related Facilities, Effects of Welding Parameters on Toughness and Hardness in 690 Weld Zone MPa Steel. 0

endstream

endobj

1 0 obj

<>

endobj

2 0 obj

<>stream

196 0 obj

<>stream

%PDF-1.4

%

Enter the email address you signed up with and we'll email you a reset link. @G`d%SS\L% .78Q$O-W%

_X8QD_bzOtI %%EOF

63 0 obj

<>/Encrypt 58 0 R/Filter/FlateDecode/ID[<9F6CE24FD48E4072E4DCE529F1E0F2E7>]/Index[57 16]/Info 56 0 R/Length 52/Prev 47238/Root 59 0 R/Size 73/Type/XRef/W[1 2 1]>>stream

dj',iS Sorry, preview is currently unavailable. and thermocouples or contact thermometers. !lrp[ 4XE)\##,%s0o0Z\o}mw1h~l@{Emuo@5srjSOyJ]P_jWKJ=`\d:NTZB=_>2}vy8VNtP(F 8z:YORhFMD (M5zr0 s

Subscribe to our newsletter to receive the latest news and events from TWI: Preheating is the process applied to raise the temperature of the parent steel before welding. BS EN ISO 13916:1997: 'Welding: Guidance on the measurement of preheating temperature, interpass [interrun] temperature and preheat maintenance temperature', British Standards Institution, 1997. %PDF-1.5

%

(See FAQ: Which is important - Preheat or interpass?). The choice of method of applying preheat will depend on the material thickness, weldment size and the heating equipment available at the time of welding. The reduction in hydrogen reduces the risk of cracking. The methods can include furnace heating for small production assemblies or, for large structural components, arrays of torches, electrical strip heaters, induction heaters or radiation heaters. @W:=.g( ECUJ3t,fB:*9 lQ q{D{# lfq)F-Q X_H$P?kBth;Tv1BD3Rd4Fu,PX" ,9^Mvdce-5v7MLbY6=81j\`04gKtEoZ4"4%q4^a

[JqJ"OhQ{=4e"=u?=U#z5

daCl^9

NC',2#nHo]w1pqsV0Bj[Ytexc6|;q-y~:e"d+GpNi!]T[

25* )V?,6

You can download the paper by clicking the button above. endstream

endobj

58 0 obj

<>>>/Filter/Standard/Length 128/O(0K`dT-B\()/P -1340/R 4/StmF/StdCF/StrF/StdCF/U(dhq )/V 4>>

endobj

59 0 obj

<>

endobj

60 0 obj

<>

endobj

61 0 obj

<>stream

API RP 582 2016 Welding Guidelines for the Chemical Oil and Gas Industries, Effect of Preheating Temperature on the Mechanical and Fracture Properties of Welded Pearlitic Rail Steels, Main book CSWIP 3 1 Welding Inspector WIS, The serviceability of a product Fabricators' and Erectors' Guide to Welded Steel Construction, Faculty of Technology Mechanical Engineering Laboratory of Welding Technology FEASIBILITY STUDIES OF THE WELDABILITY OF STRUCTURAL STEELS USED IN THE OFFSHORE ENVIRONMENT, Bisalloy Technical Manual BISPLATE Technical Manual Bisalloy Technical Manual, Welded Connections- A Primer for Engineers, MAGS Welding Arc Physics and weld pool behaviour, Welded Connections - For Primer Engineer.pdf, Mechanical and fracture analysis of welded pearlitic rail steels, P91 and Beyond Welding the new-generation Cr-Mo alloys for high-temperature service, Diffusible hydrogen in steel weldments - a status review, Weldability characteristics of shielded metal arc welded high strength quenched and tempered plates, Welding Characteristics of Ultrahigh Strength Steel in Annealed and Quench-Tempered Conditions, Welding and weldability of candidate ferritic alloys for future advanced ultrasupercritical fossil power plants, Avesta Welding AB AVESTA WELDING MANUAL Practice and products for stainless steel welding The AVESTA WELDING MANUAL, On welding gray cast iron using SMAW and GTAW process, A DESIGNERS' HANDBOOK SERIES N O 9 002 WELDING OF STAINLESS STEELS AND OTHER JOINING METHODS, Welding of Pipelines and Related Facilities, Effects of Welding Parameters on Toughness and Hardness in 690 Weld Zone MPa Steel. 0

endstream

endobj

1 0 obj

<>

endobj

2 0 obj

<>stream

72 0 obj

<>stream

hb```f``2e`c` @ PI +A~Ox?nq0t!GFGKG)+D47ILLWn13}cpBc1X]]@{8c8( hbbd``b`:$C~ "X@,svX6 T+4x`

` 6({

0

hSn@}lU.EHiBPl5.lQgf|AVV3;c@0d `q0iY]]Lb4HWEn2p &r0+enBY@xIVi &y4jBewT-unH~>t1PF.d]1b?8hx6^VWlbk_ih9&[QAY4)"26

6.*?$K|i&xd+u]%z'bkJs$%;4 Qw5 hbbd``b`Z$ @ H0?N$ g0 2l

wIeHI^)4

%Sk_{@oCD3"|aM;0$qki&Ew}c_S3,)mVuOr=}PM8((yo!Vh$ZhG^:

x7CqMDb}BgW[n|'.F8) 176 0 obj

<>

endobj

To slow the cooling rate of the weld and the base material, potentially resulting in softer weld metal and heat affected zone microstructures with a greater resistance to fabrication hydrogen cracking.

72 0 obj

<>stream

hb```f``2e`c` @ PI +A~Ox?nq0t!GFGKG)+D47ILLWn13}cpBc1X]]@{8c8( hbbd``b`:$C~ "X@,svX6 T+4x`

` 6({

0

hSn@}lU.EHiBPl5.lQgf|AVV3;c@0d `q0iY]]Lb4HWEn2p &r0+enBY@xIVi &y4jBewT-unH~>t1PF.d]1b?8hx6^VWlbk_ih9&[QAY4)"26

6.*?$K|i&xd+u]%z'bkJs$%;4 Qw5 hbbd``b`Z$ @ H0?N$ g0 2l

wIeHI^)4

%Sk_{@oCD3"|aM;0$qki&Ew}c_S3,)mVuOr=}PM8((yo!Vh$ZhG^:

x7CqMDb}BgW[n|'.F8) 176 0 obj

<>

endobj

To slow the cooling rate of the weld and the base material, potentially resulting in softer weld metal and heat affected zone microstructures with a greater resistance to fabrication hydrogen cracking.